Can your business effectively manage the sourcing and procurement of direct materials? Or do you struggle to get all raw materials, parts and assemblies listed in the bill of materials (BOM)?

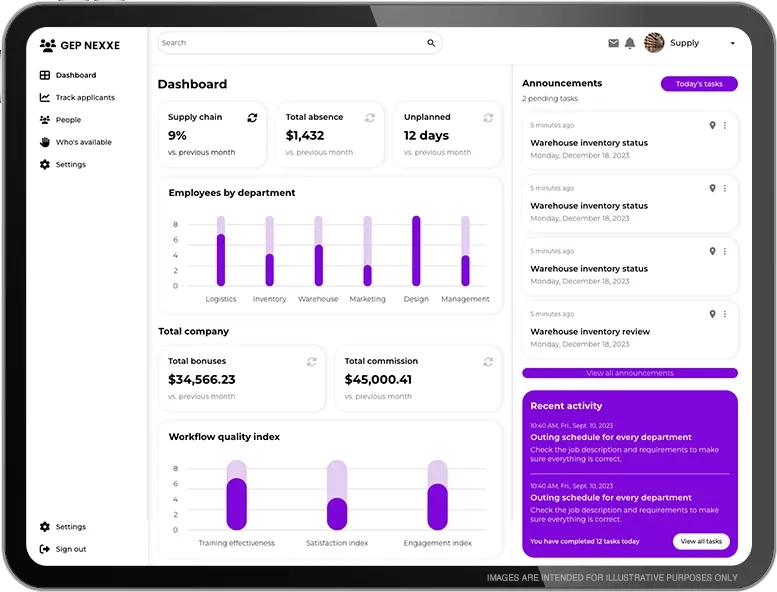

The GEP NEXXE BOM management software enhances collaboration between internal teams, contractors and suppliers. It simplifies workflows by synchronizing data from multiple MES, ERP and PLM systems.

Improved collaboration keeps stakeholders aligned, controls costs, optimizes inventory and ensures customers receive quality products on time and at the right price.

Explore the Powerful Features of GEP NEXXE BOM Management

Single, Unified Platform for Multilevel BOMs

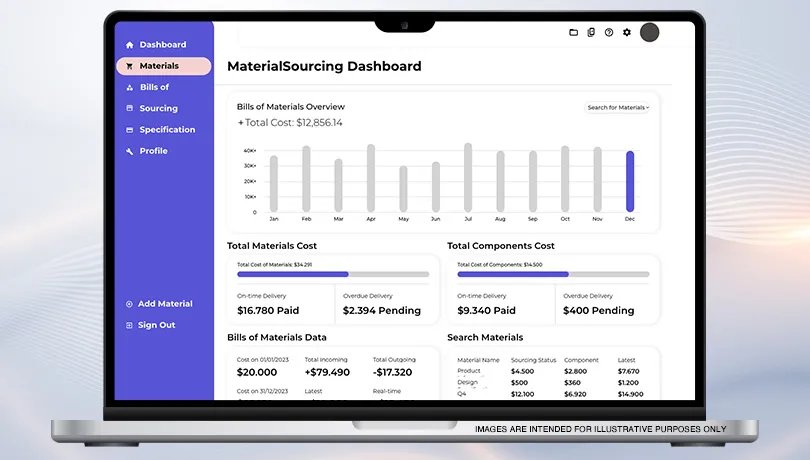

Integrate with all major ERP systems to retrieve, synchronize and manage master data. Get real-time access to all critical data related to BOMs.

Integration with Sourcing

Avoid production delays by integrating multilevel BOMs and their components with sourcing and gain real-time visibility into updated designs and specifications.

New Product Introductions

Enable engineering and manufacturing teams to build better products faster, using the right materials while keeping costs in check.

Quality Management

Facilitate seamless collaboration between suppliers and internal stakeholders for quality management — from initial sample inspection to complaint processing and audit management.

What-If Capabilities

Use what-if capabilities to evaluate make-versus-buy decisions, maintain alternative components and perform cost roll-up and drill-down analyses for different BOM versions.

Effective Collaboration

Drive innovation through effective collaboration with suppliers, enable line-item level visibility to display approved vendor numbers and buyer part numbers for BOM components.

Why Choose GEP NEXXE BOM Management Software

- Get Better Visibility and Control: Get comprehensive visibility of all BOM items throughout the product life cycle to gain better control

- Allow All Teams to Work Together: Enable effective collaboration between internal and external stakeholders to simplify workflows

- Enhance Process Efficiency: Streamline source-to-pay, plan-to-produce processes for hierarchical, multilevel, multidisciplinary BOMs

- Drive Innovation: Accelerate product innovation and introduction of new features to increase efficiency, while keeping costs in check

- Minimize Errors: Improve product quality and safety and minimize the chances of manufacturing errors and defects

- Improve Compliance: Streamline multilevel BOM management to improve compliance with global regulatory standards