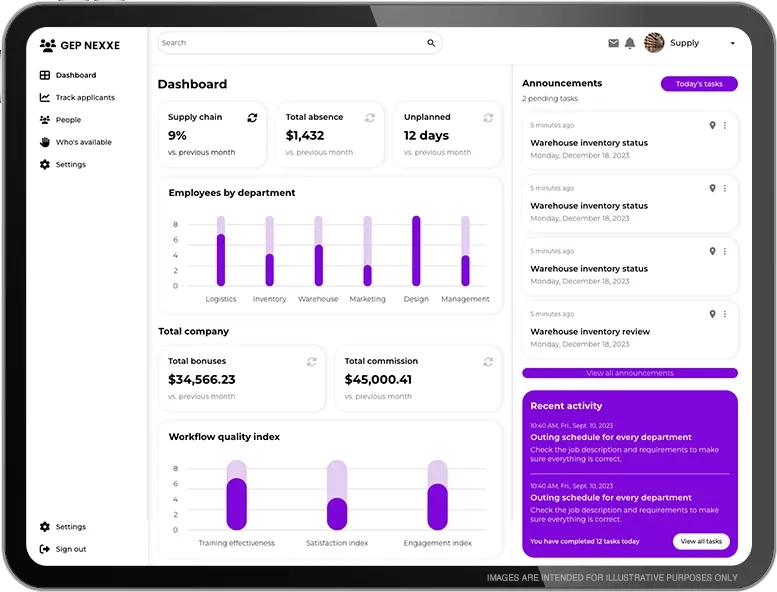

Control Tower delivers real-time visibility into your entire supply chain operation through the GEP NEXXE platform. It provides a comprehensive, unified view of key stakeholders — from trading partners and suppliers to logistics providers — enabling you to monitor, manage, and optimize your supply chain with ease. With customizable filters, you can prioritize data points, drill down into actionable details, and make informed decisions faster. Powered by GEP QUANTUM, our proprietary AI technology, predictive alerting helps your organization stay ahead of potential roadblocks and ensure seamless supply chain performance.

A Digital Control Tower to Monitor Your Entire Supply Chain

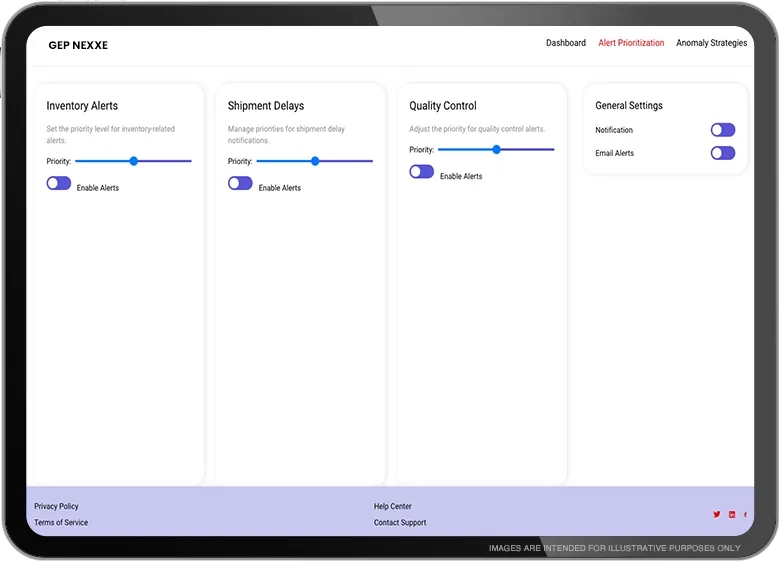

Predictive Alerting

The tower analyzes data patterns to identify potential supply chain detours and then quantifies their impact. Users can prioritize alert types and determine strategies to neutralize the impact of anomalies.

Situation Room

Collaborate to handle action items immediately and effectively. Track problem sources, assign role-based teams, create action-oriented objectives, and gauge the impact of deviations in real time with other users.

Artificial Intelligence

Leverage GEP QUANTUM, our proprietary AI technology, with algorithms that self-correct and deliver actionable, nuanced insights that increase in accuracy over time through an autodidactic learning system.

Scalable Architecture

GEP NEXXE’s API shares data seamlessly with legacy ERPs and easily integrates future tech. The design avoids hardwired legacy elements for flexible updates and smoothly deploys data visualization tools and SAP modules.

Action Status Tracker

Gain real-time visibility on the status of an individual action relative to resolution objectives in the situation room. Gauge the business impact of actions and determine the best way to move forward.

Recommended Actions

Leverage AI-powered recommended actions based on contextual and historical information along with the business impact of a potential direction. Improve planning and productivity and drive value with accurate forecasting.

One Platform for Total Visibility

End-to-End Visibility

Gain end-to-end supply chain visibility with real-time status updates on customer and geographic hierarchies. Collaborate with partners and allow them to work with internal teams to execute objectives.

Data Workflow Management

Leverage ML to create and enforce data validation and accuracy rules. Track orders at each supply chain stage with granularity about every item. View location, project and time data in one place.

Complete Collaboration

Situation rooms enable team collaboration to resolve issues with flexible role assignments. Work with partners for real-time updates. Allow suppliers to engage multiple internal teams. Share files for clarity.

Easy-to-Use Platform

Integrate multiple ERPs and unlock data’s full potential without specialized IT teams and consultants or coding knowledge. Improve planning and productivity and accelerate the implementation cycle.

Integration with Zero Disruption

Easy to integrate and use. No downtime or on-site install, for zero business impact. Built for the cloud on Microsoft Azure. Manage multiregion hosting and ensure global visibility and collaboration.

Flexible and Adaptive

Tailor and adapt GEP NEXXE to specific needs and seamlessly extract data from your ERP system. The platform’s floating data foundation enables it to release individual functions rather than the full solution.

Frequently Asked Questions

A supply chain control tower is an end-to-end, central data hub that primarily provides real-time visibility across the entire supply chain. The control tower provides a holistic and centralized view for supply chain stakeholders — from trading partners to suppliers to logistics partners, down to real-time visibility of supply chain status and activities.

A supply chain control tower allows for a single version of truth across functional boundaries, and across suppliers, contract manufacturers, transportation carriers, and third-party logistics, so that supply chain teams can take the best actions collaboratively.

The three essential capabilities of a supply chain control tower are:

- To provide real-time visibility across and between disparate supply chain functions and partners

- To promptly establish the business impacts of deviations from what was planned

- To orchestrate corrective and collaborative actions between all appropriate stakeholders

AI- and ML-enabled supply chain control towers offer predictive/prescriptive alerting and analytics, scalable data architecture and data lake, as well as automating and tracking the resolution and actions taken. They enable multi-tier supplier ecosystem collaboration.

- Combining these capabilities and more, self-tuning autonomous supply chains platforms are the future where the supply chain control tower will play a key role by further improving its proactive problem-solving capabilities and build efficient, resilient and sustainable supply chains.

- The end result is enhanced supply chain collaboration, better risk mitigation capabilities, and on-time delivery.

With increasing complexities in global supply chains, enabling real-time decisions is becoming critical to functioning. Implementing a supply chain control tower involves a complete supply chain assessment to help find and fix gaps in an enterprise’s supply chain, thereby helping the enterprise to define the business objectives of the control tower. Once the parameters and objectives are defined, the control tower can keep track of problem sources, determine the impact of any deviation in real time, and accordingly create resolution objectives.

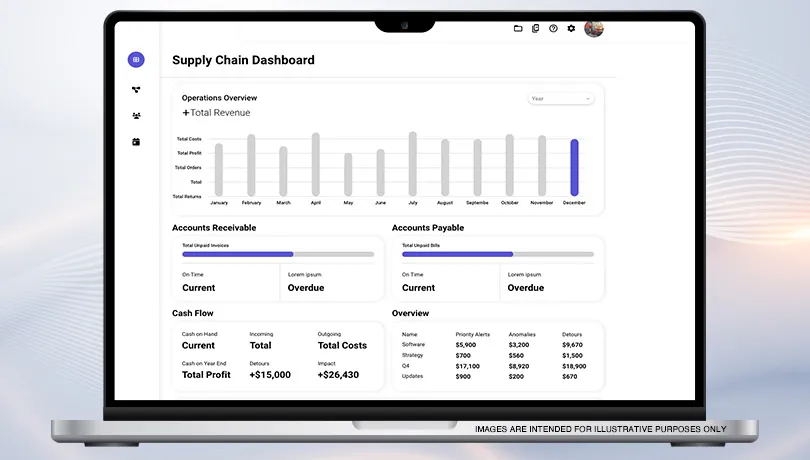

Supply chain control tower software is capable of analyzing and integrating multiple data streams across the supply chain. It enables enterprises to gain real-time visibility into inventory, orders, shipments, and disruptions with the help of interactive dashboards and analytics. The end result is enhanced supply chain collaboration, better risk mitigation capabilities, and on-time delivery.

As the name suggests, a supply chain control tower acts as a central command center that enables complete visibility, collaboration, and analytical capabilities necessary for enterprises to manage supply chains effectively. Benefits of supply chain control tower include:

- Increased visibility

- Improved decision-making

- Enhanced collaboration and coordination

- Risk mitigation and exception management

- Optimized inventory management

- Improved customer service

- Cost savings and operational efficiency

- Scalability and agility

A control tower centralizes data integration and analysis, which in turn enables enhanced supply chain visibility. By aggregating real-time information from various sources, a control tower is able to provide a holistic view of the entire supply chain. Furthermore, supply chain control towers can now leverage advanced analytics and AI to forecast disruptions and demand fluctuations in order to enable proactive decision-making.

A control tower with its ability — to monitor performance metrics, manage exceptions, optimize inventory as well as track multiple shipments in real time — can enable enterprises to proactively identify risks, evaluate supplier performance, and arrive at data-driven decisions. Implementing a control tower can unlock end-to-end supply chain visibility, helping enterprises bring agility and efficiency in supply chain operations.