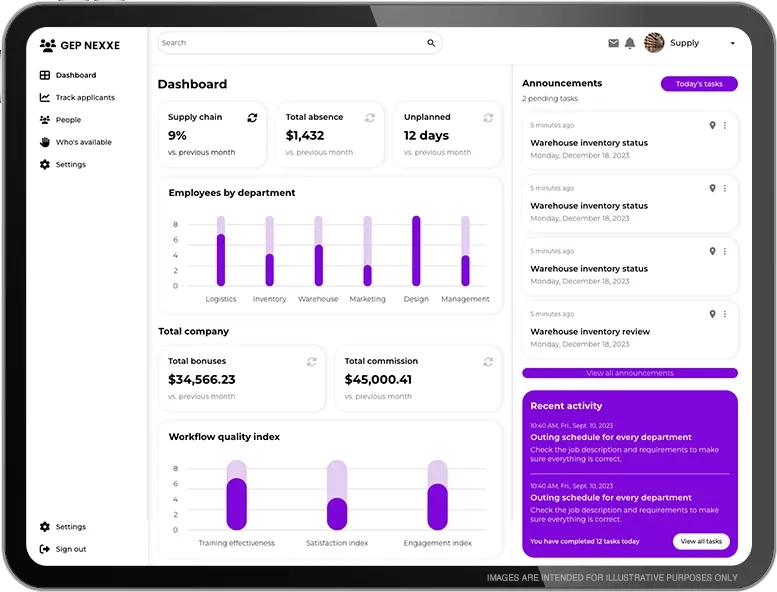

Overcome procurement challenges and unlock potential with GEP's unified end-to-end procurement and supply chain platform. Gain visibility into spending patterns, categories, suppliers and risks to make informed, optimized sourcing decisions.

Power Intelligent Direct Sourcing

Take control of complex direct material procurement with our AI-powered platform. Our centralized hub integrates bill of materials, technical specifications, and cost drivers to streamline sourcing events. With advanced analytics and real-time market intelligence, you'll make more informed decisions while our automation handles routine tasks.

Why Choose GEP Direct Material Sourcing?

Manage Costs, Improve the Bottom Line

Achieve the best cost-quality balance, ensure compliance, speed up time to market and strengthen connections with suppliers and customers.

Mitigate Disruptions

Access real-time supplier data and market intelligence to prevent disruptions. Improve agility and resilience using GEP Supply Chain Collaboration.

Streamline Complexity

Simplify direct material sourcing with a unified platform offering shared visibility of data for efficient operations.

Build Resiliency and Sustainability

Enhance collaboration, gain visibility, select the right suppliers and ensure compliance for a resilient and sustainable supply chain.

Optimize Sourcing

Improve direct material sourcing and margins, ensuring updated BOM lists and accurate production designs.

Identify Cost Drivers

Use should-cost modeling, cost breakdowns and scenario analysis to understand and manage cost drivers effectively.

Key Features

Organizations face procurement challenges because of a lack of visibility to key data such as complete picture of supply costs, supplier risk and performance, complexity of manufacturing processes, and difficulty monitoring and mitigating risk associated with the supply chain network. GEP Direct Material Sourcing offers a variety of features to remove these obstacles, including:

Get a consolidated view of all item-related activities, including RFx, contracts, BOMs and demand. Access visibility when sourcing, viewing price sheets or reviewing contracts.

Evaluate bids, contracts and purchase orders to estimate costs before a sourcing event or negotiation. Sophisticated cost-driver analysis allows you to understand all driving factors for cost drivers. The category-based market intelligence offers more than 75K global price indices, detailed data on 60+ countries.

Integrate seamlessly with leading ERP, MES and PLM systems to centralize, synchronize, and manage supplier and item master data. Ensure data accuracy through normalization, error detection, correction and consolidation.

Import bills of materials from multiple systems and gain real-time visibility into all BOM items including latest specs, inventory, order status, contracts, supplier information, and shipment status. Choose a BOM from the repository and choose alternative costing scenarios for the parts in that BOM to understand the total cost of the product.

A single end-to-end category-intelligence hub that enables visibility and oversight into spend for all category-related sourcing activities and guides the execution of various sourcing strategies based on key drivers, gathered insights, and AI-based recommendations within the powerful category workbench.

Automate sourcing events, RFQs, and contracts, with pre-built templates and workflows, to streamline sourcing processes and reduce errors.

Leverage advanced analytics and reporting to gain visibility into spend patterns, supplier and trading partner ecosystem, and associated risks and costs.

The system enables collaborative workflows, which are easily utilized across your organization from category managers and sourcing managers to product managers.