Today’s supply chains are dynamic, with demand shifting quickly to meet customer needs. To stay profitable, your supply chain management (SCM) efforts must be flexible and precise. Closed-loop supply chain software enhances visibility into demand signals and supply, allowing you to anticipate challenges and plan ahead.

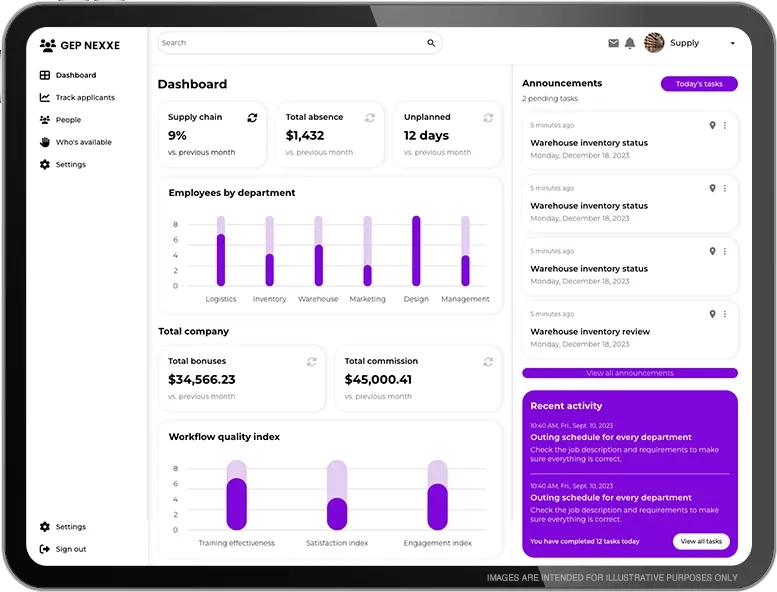

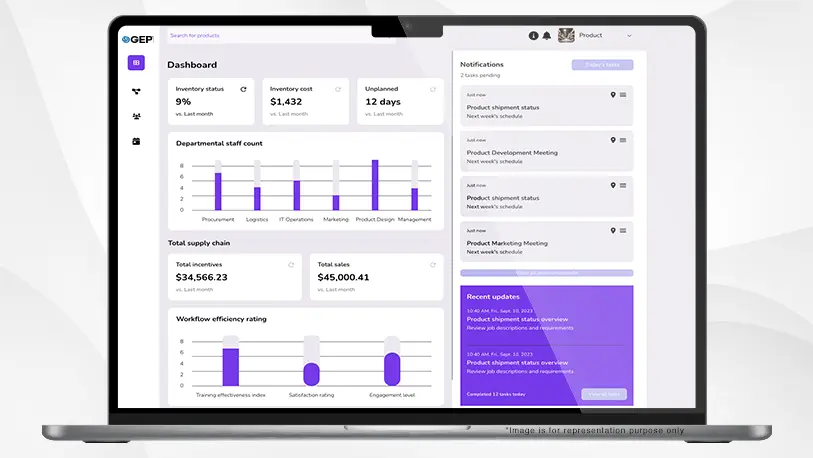

GEP NEXXE™ Supply Chain Planning offers a best-in-class, closed-loop solution that optimally matches demand and supply in real time, helping you make the best business decisions. Improve service levels, ensure on-shelf availability and provide reliable customer commitments with agile, cost-effective supply chains.

Ensure End-to-End, Real-Time Demand and Supply Matching

Supply Chain Digital Twin

Create a digital representation of your entire supply chain, including suppliers, manufacturers, and distribution networks

Closed-Loop Planning

GEP NEXXE integrates demand planning and supplier collaboration on one platform, giving a true view of market needs and supply constraints. Meet customer commitments with confidence

Constrained / Semi-Constrained Planning

Increase planner efficiency and maximize demand satisfaction by considering material and capacity constraints

Demand Prioritization

Enforce business policies and prioritize demand based on your goals, such as revenue, demand satisfaction, and customer satisfaction

Rapid Scenario Planning

Quickly create and analyze different scenarios to optimize your supply chain, considering metrics like demand satisfaction, revenue, and cost

Integrated Planning

Generate procurement, production, and distribution plans for seamless execution and collaboration with suppliers and contract manufacturers

Optimize Your Supply Chain with GEP NEXXE Closed-Loop Planning

- Boost Revenue: Increase revenue by 1-5% with better demand fulfillment and real-time supply realignment to market changes.

- Reduce Inventory Levels: Cut inventory by 20-30% using efficient planning, just-in-time inventory, and demand-driven stock adjustments.

- Reduce Expedite Costs: Lower expedite costs by optimizing capacity utilization through proactive supply chain planning.

- Improve Productivity: Automate supply plans and manage exceptions to improve productivity. Focus on resolving key constraints.

- Optimize Global Plans: Use multi-enterprise models to create plans that minimize excess and manage supplier constraints.

- Rapid What-If Scenarios: Respond to market shifts with fast, alternative plans for demand or supply fluctuations and secure business.