Still Exploring Use Cases? Here’s Where AI Can Make Real Impact in Procurement & Supply Chain

- The adoption of AI is radically changing procurement and supply chain operations.

- From sourcing and supplier selection to contract and inventory management, AI can automate core processes in procurement.

- AI can also fill organizational gaps and synchronize different business functions to boost procurement orchestration.

November 16, 2024 | Technology 6 minutes read

Do businesses understand how they can make the best use of artificial intelligence?

No doubt, almost all of them recognize the transformative potential of AI.

But while some of them have already adopted this technology or plan to adopt it soon, others are still exploring its use cases.

And this is also the case with individual business functions such as procurement and supply chain.

Up to 74% of chief procurement officers plan to deploy AI by the end of this year, suggests a survey of 382 CPOs and other procurement executives conducted by Ardent Partners between January and March this year.

As many businesses look to accelerate AI adoption, they also need to build a strong business case and find specific answers to how they can make the most out of this technology.

For procurement and supply chain professionals, the key question is: How can the deployment of AI benefit their day-to-day operations? What are its typical use cases? And what should they consider before deploying this technology?

Let’s take a deep dive into the fast-emerging AI-powered procurement and supply chain landscape.

The Leadership’s Belief

Firstly, procurement leaders believe that the function has an opportunity to go beyond its traditional responsibilities and play an increasingly vital role in the overall business. 65% of CPOs expect their teams to deliver more value than last year, suggests the Ardent Partners survey.

To play a more strategic role and deliver additional value, they must adopt (as well as understand) technology. 61% of CPOs agree that AI will have a transformational (17%) or significant (44%) impact on procurement.

In another survey conducted by Economist Impact, 65% of chief supply chain officers said they believed generative AI could automate between 26% and 50% of their procurement and supply chain operations over the next 3 years.

What then will procurement professionals do when core processes are automated? Let’s find out.

The Prominent Use Cases

As the results of the above surveys suggest, the popular opinion today is that AI is going to be a vital component of future procurement and supply chain strategies. The question now is: Where can its deployment make a significant impact?

Let’s look at the key use cases:

1. Sourcing:

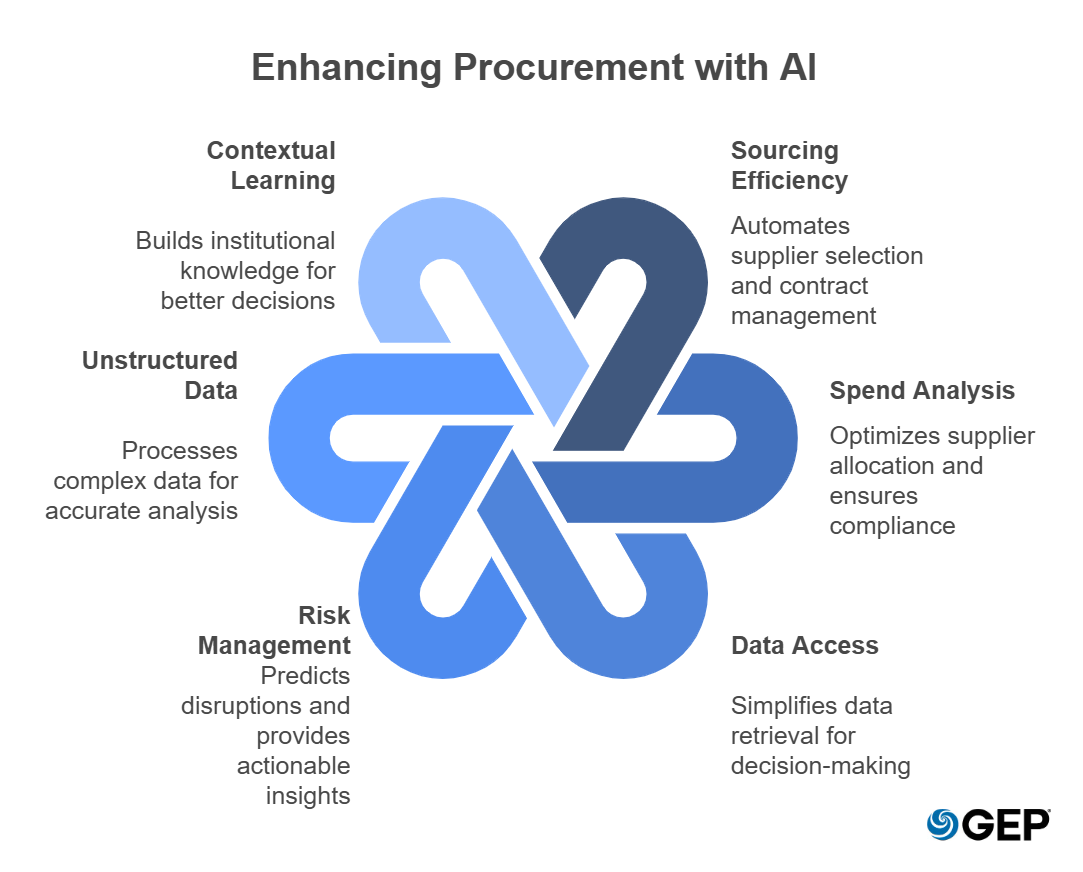

The adoption of AI can automate core procurement processes such as sourcing, supplier selection, contract management and vendor relationship management. By automating these tasks, AI can help procurement achieve greater engagement, speed and efficiency. This also means that procurement can do more with less resources and focus its resources and time on more strategic tasks.

2. Spend analysis and contract management:

Using optical character recognition, AI algorithms can scan through millions of invoices, contracts and complex web documents to enhance spend visibility by supplier groups, regions and down to category levels. Teams can leverage this spend analysis to improve their strategic supplier allocation decisions and better negotiate contracts. Likewise, technology can quickly analyze legal documents and complex contracts. It can extract key terms, milestones and SLAs in minutes to build compliance dashboards for review by experts.

3. Access to data and intelligence:

Procurement needs a lot of information in its daily operations, and this is perhaps where AI can help the most. AI provides easy access to data and intelligence and reduces the effort needed to retrieve information. This removes the need for analytical skills and information retrieval routines between the requester and the data source, says Paul Blake, senior director of product marketing at GEP.

Procurement teams can leverage intelligence and look through the data to simplify core tasks. For example, they can identify the most suitable suppliers based on predefined parameters such as pricing, quality, delivery record and sustainability performance.

4. Planning and risk management:

With its ability to quickly analyze vast amounts of data and generate predictive insights, AI can also aid in building pre-emptive plans and rapid response to procurement and supply chain disruptions. This capability can prove to be a game-changer for organizations amid the prevailing uncertainty. For example, AI systems can analyze data related to geopolitical events, natural disasters or market fluctuations and provide early warnings. They can create synthetic data and models to facilitate simulation, scenario planning, risk assessment and compliance. Further, they can also identify specific risks associated with suppliers and trading partners and suggest proactive steps to mitigate their impact. They can even recommend alternative suppliers to respond swiftly to any disruption.

5. Processing of unstructured data:

With generative AI, procurement and supply chain managers can make sense of complex unstructured data such as inventory levels and supplier performance. They can use technology to identify gaps in the data and make sense of incoherent variables. They can also ask questions in natural language to get credible, data-backed answers for accurate spend analysis.

6. Contextual understanding and cross-domain knowledge:

When trained on diverse data sources such as contracts and spend data, AI systems build institutional knowledge and capture the nuances of business processes and category taxonomies. They expand contextual understanding to enhance contract analysis and spend classification and refine their output over a period. Generative AI tools, for example, retain context during conversations and refer to previous messages to facilitate meaningful interaction. By engaging with users across procurement and supply chain, they can also gain visibility into interdependencies and connect the dots to facilitate effective communication and decision-making.

The Orchestration Advantage

Orchestration is the bringing together, with the help of AI, of procurement processes, resources and technology across multiple categories, regions and business units. This allows the function to strategically manage spend, suppliers and contracts at scale while catering to stakeholder-specific requirements.

AI enables procurement to synchronize processes within the intake and source-to-pay cycle. This simplifies complex processes by integrating systems and stakeholders into a cohesive workflow. It allows different business functions to work closely by seamlessly exchanging information and tasks. It also centralizes the management of technology by integrating disparate systems into one unified architecture. Further, this helps internal business teams by providing a single point of contact within procurement.

The Things to Consider

AI solutions are deeply embedded into enterprise applications for making recommendations and predictions and improving decision-making. It is therefore vital to determine whether AI can deliver ethical, responsible and reliable solutions.

Additionally, enterprises need to identify relevant and unbiased internal and external data sources to make high-quality data available for interpretation by AI tools.

Not only do organizations need to perform a critical evaluation during the time of technology selection, but they also must establish a continuous review program to validate the solution’s alignment with business goals and values.

Enterprises must try to seek answers to the following questions:

- Does the AI solution optimize business outcomes and deliver high value to the organization? How does it align with the long-term business strategy?

- Does the AI solution meet the business and regulatory data protection requirements? What data does it need and how can you collect and cleanse it?

- Does the AI solution provider align with your organizational values and ethical standards?

- How can you conduct an initial impact assessment to check ethical, equitable and sustainable deployment?

- How can the AI solution be integrated into core processes?

The Role of Human Intervention

Despite its huge potential in procurement and supply chain operations, AI cannot do everything on its own. Businesses need human expertise and insight to complement technology solutions. They can use their knowledge and skills to validate the results or analysis.

This also means that businesses increasingly need a skilled workforce that can work easily with AI and digital tools to achieve the desired results. They must synchronize the efforts of people, processes and systems. When they get this synchronization right, they can make the best use of AI and achieve their business goals.

The Need to Act Now

Finally, businesses need to move fast and not spend too much time contemplating AI’s potential use cases. They should adopt an ‘on-the-job training’ approach and become familiar with the new digital tools.

Introducing AI in a function such as procurement where it can make a huge impact can be a good way to start. Once the team understands how to make the best use of technology, it can accomplish tasks with ease, and the program can then be expanded to different functions.