Best Practices to Optimize Procurement Lead Time

- Reducing procurement lead time boosts customer satisfaction and retention by enabling faster deliveries.

- Shorter lead times minimize the risk of product obsolescence, ensuring offerings remain relevant and in demand.

- Implementing technology and supplier optimization reduces operational costs while improving efficiency across the supply chain.

November 16, 2024 | Procurement Strategy 5 minutes read

When it comes to optimizing procurement lifecycles and timelines, there's one denominator that emerges as a key factor —procurement lead time.

Procurement lead time impacts the efficiency and success of supply chains.

Whether dealing with products or services, understanding and optimizing lead time can lead to better customer satisfaction, lower inventory costs and faster market responsiveness.

This blog will explain the tangible benefits of reducing procurement lead times and best practices to optimize it.

Strategic Values of Lesser Procurement Lead Time

1. Creating Happier Customers

Quick delivery is a top priority for customers. Lesser procurement lead time allows you to deliver products to your customers quicker. Doing so will lead to enhanced customer retention and loyalty, eventually increasing customer lifetime value. Additionally, prompt order fulfillment helps you stay competitive in markets where customers expect fast turnarounds.

2. Reduced Risk of Obsolescence

Lesser procurement lead time ensures your products stay up-to-date and relevant to the market before they become available, especially in rapidly evolving industries. When the time between product conception and delivery is reduced, you ensure your offerings remain relevant and in demand. This leads to a reduction in the risk of inventory waste, markdowns and lost sales due to products going out of date. This also allows you the agility to be more responsive to changing market trends and customer preferences.

3. Lower Labor Costs

Shorter lead time save operational costs while boosting productivity. Streamlining your procurement process eliminates unnecessary labor hours. By optimizing order processing, inventory management and supplier communication, you reduce the time and effort needed to manage your supply chain. Automating certain aspects of procurement, such as purchase order creation and invoice processing, further reduces labor costs and minimizes the risk of human error.

Also Read: 7 Steps to Reduce Supply Chain Lead Times

4. Efficient Capital Utilization

Reducing lead time accelerates the transformation of raw materials into finished products. Faster cycles free up capital sooner, enabling reinvestment in other key business areas. Minimizing inventory time in the supply chain lowers working capital needs and enhances cash flow.

Best Practices for Achieving the Ideal Procurement Lead Time

1. Optimizing Supplier Contracts

Ensuring commitment and accountability from the supplier regarding delivery timelines is important. This can be done by incorporating lead time provisions into supplier contracts. This can help you clearly define expected lead time and specify repercussions if such deadlines are not met, for instance, penalties or the right to seek alternative suppliers.

This will make suppliers prioritize orders and optimize processes to meet delivery deadlines. These provisions can also act as a measure for supplier performance evaluation as it can allow for regular reviews. They will help you identify consistent offenders and spot opportunities for improving negotiations.

2. Accurate Demand Forecasting

Accurate demand forecasting is essential for reducing procurement lead time. It can provide your suppliers with precise and timely forecasts of your business requirements. This allows them to better prepare for and respond to your orders, streamlining the entire procurement process.

This proactive data sharing helps your suppliers stay responsive and stay on top of inventory – avoiding shortages or overstocking.

When suppliers have data to leverage for production runs, waste reduction and effective resource utilization take place – supporting environmental sustainability while driving savings.

3. Leveraging Technology

Procurement lead time can be significantly reduced through the automation of important processes via technology. Automatic order generation through procurement software reduces the need for manual paperwork thus minimizing human mistakes. Moreover, it allows for quick automatic approvals as well as real-time tracking.

In addition to advanced data analytics, as discussed earlier, artificial intelligence tools can also improve demand prediction.

Supplier management systems enhance communication between buyers and sellers while ensuring that supplier performance is monitored effectively. It can be said that technology-led optimization in procurement plays a key role in reducing lead time.

4. Optimizing Order Volume and Frequency

It can be useful to assess whether it’s more cost-effective for you to buy larger quantities less frequently or vice versa.

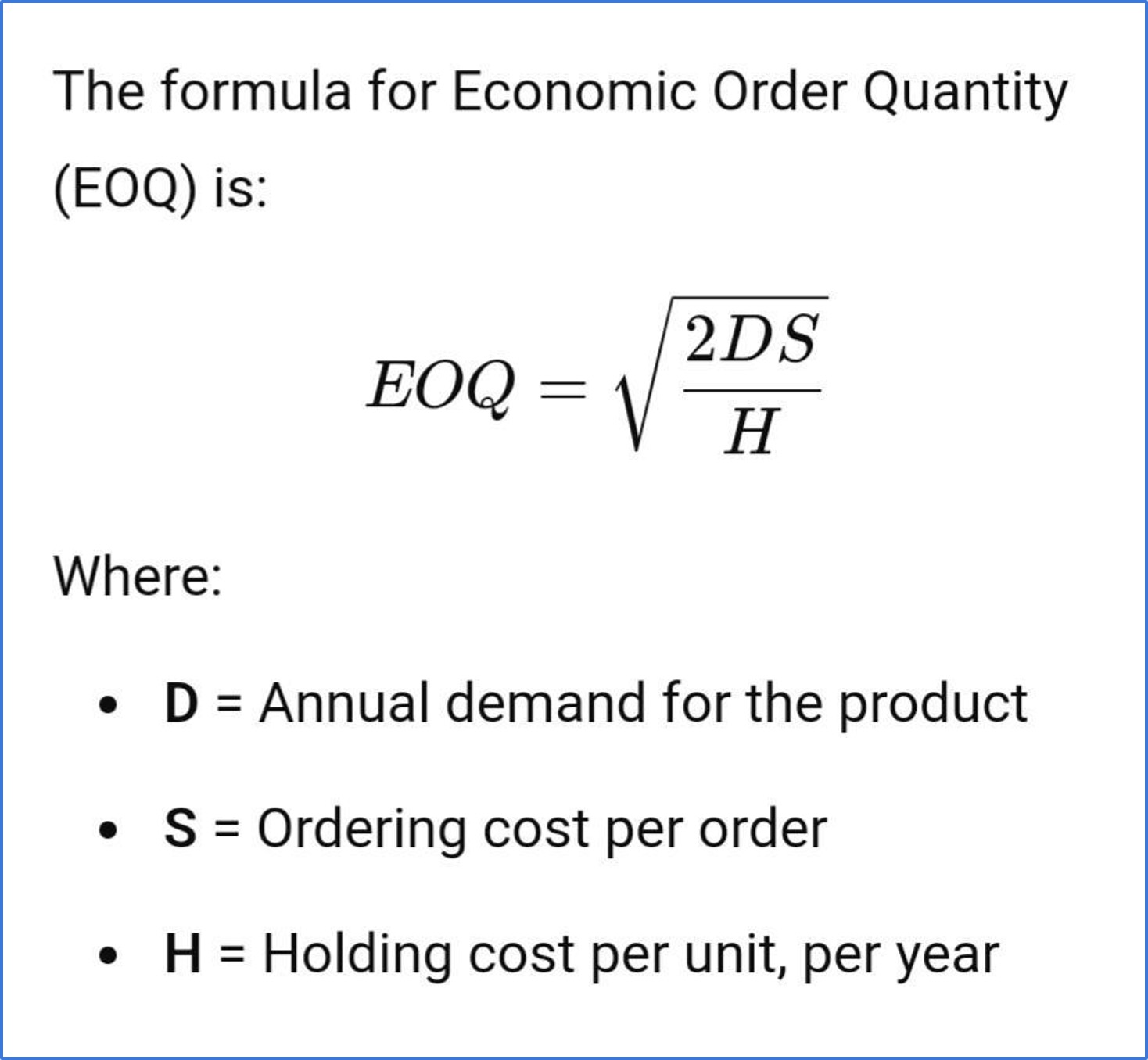

One technique to determine this is by calculating Economic Order Quantity (EOQ). Formula shown below:

As shown, this equation considers product demand, order costs and holding costs to give you the optimal number of units to procure.

This number helps you strike a balance between meeting inventory goals and optimal lead time.

Example

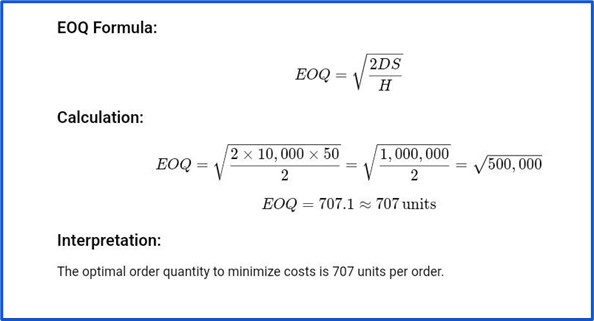

A company sells 10,000 units of a product annually. The ordering cost is $50 per order, and the holding cost is $2 per unit per year.

This means, ordering 707 units each time, the company strikes a balance between ordering too often (which increases ordering costs) and holding too much inventory (which increases holding costs). EOQ helps optimize this balance, leading to lower total inventory costs.

5. Choosing the Right Suppliers

For a responsive and reliable supply chain that enables shorter lead time, it is vital to optimize supplier relationships and monitor supplier performance.

Your strategy should include regularly evaluating your suppliers' performance against benchmarks such as delivery times, product quality and responsiveness.

Supplier scorecards can be helpful to tangibly measure performance. Based on performance results, you can identify unreliable suppliers that might cause significant disruptions to your supply chain.

Diversifying the supplier base and opting for local suppliers can also help with optimized procurement lead time even amidst disruptions.

6. Adopting Kitting Practices

Kitting is a process where individual components required for a product or process are grouped, packaged and supplied together as one unit.

This streamlines assembly and preparation stages thereby significantly reducing procurement lead time. Bundling components minimizes handling time while accelerating the overall production process.

Kitting also simplifies inventory tracking and management by reducing the number of individual items that need monitoring – making inventory more straightforward and decreasing the chances of mistakes.

It further ensures all required components are available at once, eliminating delays due to misplaced or missing parts.

Optimize Procurement Lead Time Now

Shortened lead time improve customer satisfaction, preserve operational costs while giving the best from every penny's worth. Using procurement best practices-such as better demand forecasting, leveraging technology and optimizing supplier relationships-businesses can effectively streamline their procurement processes in order to reduce lead time. Eventually, reduced procurement lead time leads to strong drives to growth and agility: the assurance of long-term success.