What is a Quantitative Supply Chain (And How It Can Improve Decision-Making)

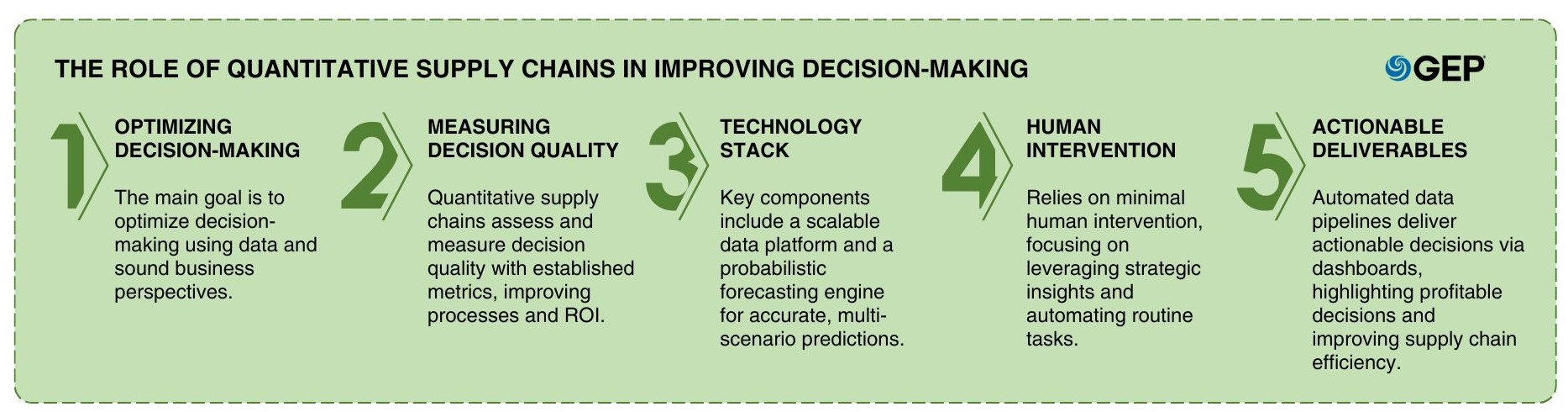

- The primary goal of a quantitative supply chain is to optimize decision-making.

- It assesses the quality of supply chain decisions on the basis of sound business perspectives.

- A data platform and a probabilistic forecasting engine are vital components of a quantitative supply chain technology stack.

May 29, 2023 | Supply Chain Software 4 minutes read

Many businesses have digitalized their supply chain operations and leveraged advanced technology in this process. Among other things, technology provides data and insights that, if used correctly, can optimize several supply chain processes.

However, businesses haven’t succeeded in optimizing processes despite having the technology in place.

The problem is their inability to use the data and insights generated by technology.

How can businesses rectify this and use these insights to improve decision-making and optimize processes?

Measuring the Quality of Decisions

Businesses must ‘quantify’ decision-making. In other words, they should assess (and measure) the quality of decisions based on sound business perspectives.

To do this, they must first establish some metrics to measure the quality of decisions made. And this is where a quantitative supply chain can help your business. It can establish the metrics needed to measure and evaluate the decision-making quality.

In the long-term, these metrics can also help assess improvements in supply chain processes and return on investment.

Improving the decision-making ability of businesses is a key objective of a quantitative supply chain. To do this, a quantitative supply chain leverages data as well as capitalizes on every human intervention in the process.

The Technology Stack

A quantitative supply chain relies on the functioning of the technology stack. A data platform with programmatic capabilities is central to its working. Programmatic capabilities allow the platform to implement any arbitrary data processing logic.

Also, as supply chains generate massive amounts of data, the data platform should be scalable and capable of processing all this data in a short period.

A probabilistic forecasting engine is another key requirement of a quantitative supply chain technology stack. Unlike a classic forecasting approach that predicts a single forecast that often turns out to be inaccurate, probabilistic forecasting predicts multiple probabilities in the future. It weighs in uncertainty and prepares a business for multiple possibilities.

In a lead-time forecast, for example, it assigns a probability to all possible lead time durations. The demand forecast is then built on top of lead-time forecasts provided as inputs.

The Human Intervention

Unlike traditional supply chain solutions that consume human effort to make several decisions, a quantitative supply chain capitalizes on human intervention to leverage insights and make informed decisions. In this process, it also fixes the root cause of manual intervention.

A quantitative supply chain can run with a lean human workforce.

While it doesn’t need people to be involved in the complex ‘technicalities’ of a solution, it does require supply chain leadership to step in and execute the strategic insights. It also requires a supply chain coordinator who can gather feedback from internal teams, communicate with all parties involved and clarify the processes, decisions and metrics.

Data is the lifeline of a quantitative supply chain. Every decision in the supply chain is made based on reliable data.

To ensure that data is readily available, it needs a data officer who can supervise all the data extraction process for daily operations.

Finally, a data scientist uses technology to combine the data and insights and automate the production of decisions.

The Deliverables

Delivering decisions that are actionable is the primary goal of a quantitative supply chain. To achieve this goal, it focuses on creating fully automated data pipelines. This implies that data collection and processing is automated and does not involve manual operation.

The deliverables are represented in the form of ‘scripts’ that are written in a programming language.

However, instead of scripts, end-users may expect a more tangible output from a quantitative supply chain. They would look at the dashboards containing consolidated KPIs and tables with suggested decisions.

Dashboards can consolidate the decisions obtained as the final numerical result in the data pipeline. They can also compile prioritized decisions based on their financial outcomes. In other words, they display highly profitable decisions at the top and unprofitable decisions at the bottom.

Conclusion

A quantitative supply chain is not an all-encompassing solution that aims to fix everything in a company’s supply chain. It focuses specifically on improving the decision-making capability and can deliver tangible results in this regard.

The decisions generated by the system are actively used and their results are monitored over time. These results may not be visible immediately. It may take a few weeks to even a few months to assess the performance of automated supply chain decisions. Also, to enhance performance, the data scientist can fine-tune the decision-making logic by reviewing the KPIs and data quality.

Additionally, with decision-making automated, supply chain teams are no longer required to perform routine manual tasks. They can instead focus on monitoring suppliers more closely, improving processes and workflows, and other strategic tasks.