How Supply Chain Forecasting Can Help Your Business Predict Demand

- Supply chain forecasting has become vital in the current business environment.

- This helps businesses accurately predict consumer demand.

- It also helps them make informed decisions about inventory management.

November 28, 2022 | Supply Chain Software 5 minutes read

Amid growing uncertainty, it is vital for businesses to work proactively, maintain optimum inventory and stay prepared for disruption.

One of the first tasks in this proactive approach is to accurately predict demand. And this can be done with the help of supply chain forecasting.

This article will give you an overview of what supply chain forecasting is, why it’s important, and the different types of forecasting.

What is Supply Chain Forecasting?

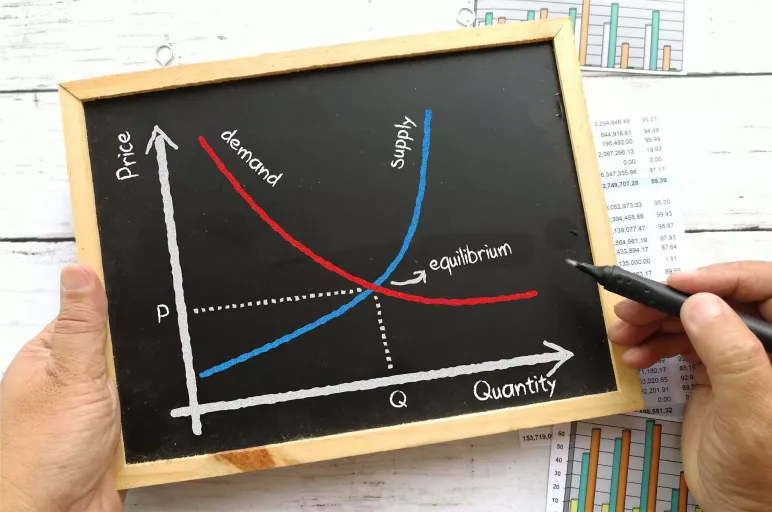

Supply chain forecasting is the process of predicting demand for products, materials or intermediate inputs. This process is critical for businesses because it helps them make better inventory management decisions and reduces the risks that come with running out of stock or having too much excess inventory.

Supply chain forecasting is used to forecast both external and internal demand across the supply chain. Externally, demand can be forecasted for your customers. Internally, demand can be forecasted for raw materials, components and finished goods.

Supply chain forecasting is a highly data-driven process. It includes planning, creating a forecast for demand and then creating a plan for how the business will meet that demand. The plan includes inventory management, service levels and procurement decisions. A supply chain forecasting software tool can help organizations create a forecast, manage their plan and monitor progress throughout the process.

Why is Supply Chain Forecasting Important?

Supply chain forecasting is critical because it helps businesses understand what the future demand will be so that they can prepare accordingly. If a business doesn’t forecast supply and demand, they could end up running out of stock, which could cost them customers. They could also end up with too much inventory, which can cost them more money than they make in sales.

By forecasting supply and demand, businesses can make the right decisions to make sure they have enough inventory on hand to meet customer demand. They can also make sure they have inventory left over in case there’s a disruption in the supply chain.

Different Types of Supply Chain Forecasting

There are many ways to forecast supply chain demand and multiple methods can be combined in a hybrid approach to meet your unique business needs. The two main types of forecasting are demand forecasting and inventory forecasting. Demand forecasting looks at what customers will buy in the future and inventory forecasting looks at the materials and finished goods that a business has in its supply chain.

Demand Forecasting

Demand forecasting looks at what customers will buy in the future. This forecasting method uses all the information available about your customers to predict their future demand. It is based on the belief that customers who bought your products in the past will buy them again in the future.

Demand forecasting can be further broken down into three categories: qualitative forecasting, quantitative forecasting, and hybrid forecasting. Qualitative forecasting uses data from the past to predict future demand. This forecasting method uses expert judgment to make predictions about what the future demand will be. This forecasting method can be effective at predicting seasonal demand and understanding why customers buy your products the way they do. Quantitative forecasting uses historical and current data to predict future demand. This forecasting method uses statistical and analytical modeling to predict the future demand. Hybrid forecasting combines the best practices of qualitative and quantitative forecasting to create a hybrid forecasting model.

Inventory Forecasting

Inventory forecasting looks at the materials and finished goods that a business has in its supply chain. This forecasting method tries to predict how much of each item the business should have in its inventory. There are many different types of inventory forecasting. The three main types of inventory forecasting are economic order quantity (EOQ), value-added forecasting, and perpetual inventory systems.

Economic order quantity forecasting uses demand forecasting techniques to determine how much of each item the business needs to have in its inventory. Value-added forecasting is a hybrid forecasting method that uses both demand and inventory information to forecast supply chain demand. Perpetual inventory systems are a type of inventory forecasting that tracks inventory as it moves throughout the supply chain. This forecasting method also uses demand forecasting techniques to determine how much of each item the business needs to have in its inventory.

Replenishment Forecasting

Replenishment forecasting looks at the inventory levels in the supply chain and determines when a business needs to reorder inventory. This forecasting method calculates the inventory and then adds some extra time to account for shipping time and other factors. The business then reorders the inventory before they run out. There are various ways to forecast replenishment.

Replenishment forecasting can be further broken down into three types: perpetual inventory systems, reorder points, and cycle counting. Perpetual inventory systems are a type of inventory forecasting that tracks inventory as it moves throughout the supply chain. This forecasting method uses demand forecasting techniques to determine when a business needs to reorder inventory. Reorder points is a hybrid forecasting method that calculates inventory levels and then adds some extra time to account for shipping time and other factors. Cycle counting is a quantitative inventory forecasting method that counts inventory levels at regular intervals to determine when a business needs to reorder inventory.

Manufacturing Forecasting

Manufacturing forecasting looks at the production process to predict when a business will have finished goods. This forecasting method can also predict when raw materials will be needed to produce finished goods. There are various ways to forecast manufacturing.

The three main types of manufacturing forecasting are build-to-order, build-to-stock, and demand-based manufacturing. Build-to-order manufacturing is a forecasting method that calculates how much finished goods a business will make based on customer orders. Build-to-stock manufacturing is a forecasting method that determines how much finished goods a business will make based on historical demand for their products. Demand-based manufacturing is a hybrid forecasting method that uses inventory data along with demand data to forecast finished goods.