How Companies Can Baseline Their Scope 3 Emissions

- A lack of data transparency and expertise has made it difficult for businesses to track and estimate Scope 3 emissions.

- There are several established methods that use primary and secondary data to baseline Scope 3 emissions.

- Procurement can play a key role in emissions mapping and baselining by using spend data.

October 16, 2023 | Supply Chain Strategy 4 minutes read

There are wide gaps between what businesses hope to achieve as part of their environmental responsibility and what is happening on the ground today. A lot of this is because these organizations are failing to collaborate effectively with their supply chain.

While many have committed to achieving net-zero emissions, businesses tend to falter at the first step of measuring their emissions, especially emissions that originate from third-party entities in their supply chains, such as suppliers or suppliers’ value chain.

Also known as Scope 3 emissions, these are one of the biggest sources of emissions and typically account for over 80% of an organization’s total emissions.

A lack of data quality, organized efforts and supplier engagement have compounded the problems of businesses and made it increasingly difficult for them to arrive at a realistic baseline.

Also read: How to Effectively Monitor Scope 3 Emissions Reporting From Your Supply Chain

So, how can companies overcome the obstacles to tracking Scope 3 Emissions?

Here are some ways they can go about this.

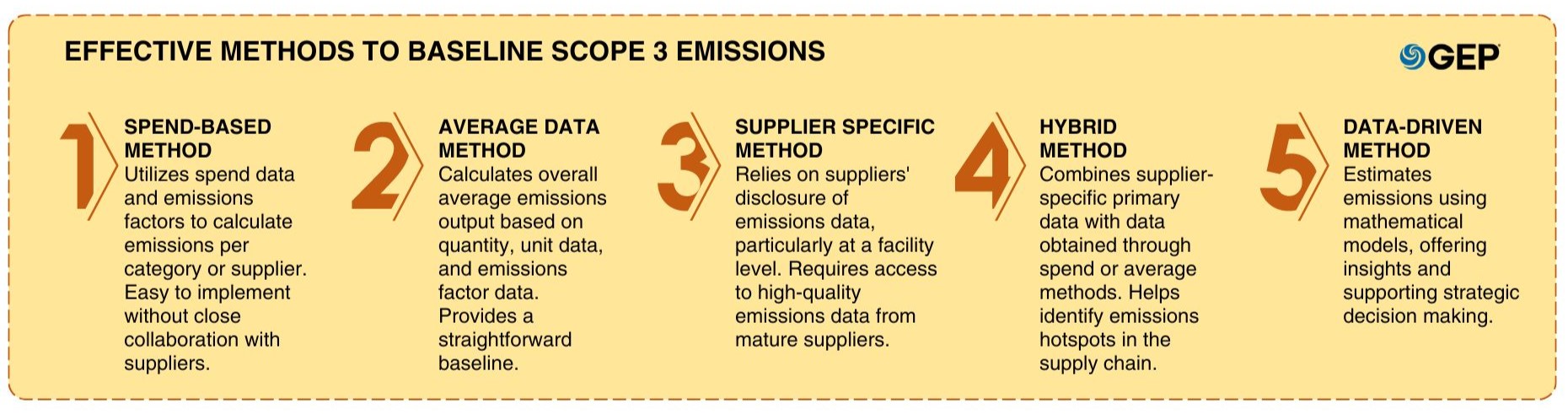

Methods to Baseline Scope 3 Emissions

1. Spend-based method:

In this method, spend data, which is readily available to procurement, is broken down into categories and commodities. Another set of data that includes emissions factors — the coefficient that quantifies the amount of emissions produced per unit of activity or product — is used as a multiplier to calculate emissions for each category or supplier.

Compared to other methods, the spend-based method is relatively easy to implement as it works with available spend data and does not need close collaboration with suppliers.

There are two types of spend-based methods:

• Environmentally Extended Input Output (EEIO) Method: To arrive at an emissions estimate, this method requires spend data for each supplier in a given fiscal year and annual emissions, which can be obtained from publicly available annual sustainability reports.

It works on the logic that the more money a business spends with a supplier, the larger is the proportion of that supplier’s emissions that the business is indirectly responsible for.

This method derives the emissions factors by dividing the supplier’s total emissions by their total revenue per year. The emissions factor is then used to calculate the contribution of a business to the supplier’s emissions based on how much it spends with that supplier.

• Category-specific method: Unlike the EEIO method, this method uses category-specific emissions factors, which correlate emissions to the amount of spend on a particular category. The attainment of category-specific emissions factors requires extensive category knowledge as well as an understanding of materials and processes used for different products and commodities throughout their lifecycle. As emissions factors are derived from variable commodity prices, this method also requires a margin to account for current market and economic trends such as inflation.

2. Average data method:

This method can be used when a business has clear visibility into their quantity and unit data as well as emissions factor data by quantity or weight. This data is used to arrive at an overall average emissions output.

3. Supplier-specific method:

This is a primary data collection method that relies on the disclosure of emissions data by suppliers, for example at a facility level. To arrive at a reasonably accurate estimate, the business must have access to high-quality emissions data from suppliers. Therefore, this method is not suitable for suppliers who are not mature enough to collect or report primary emissions data.

4. Hybrid method:

This method uses a combination of supplier-specific primary data and data arrived via spend or average methods to identify hotspots in the supply chain. Along with the secondary data, it uses primary data from select suppliers who are understood to be the highest emitters. The combination of primary and secondary data helps a business arrive at a more accurate emissions estimate.

Also read: What To Learn From Tesla’s Supply Chain Emissions Declarations

Conclusion

A key objective in the above approaches is to map out emissions, leading to a better understanding of highest-emitting suppliers and categories.

The more closely a business can work with these suppliers, the more likely it is to co-innovate, collaborate and create value to reduce emissions.

Procurement is ideally placed to use available data and existing supplier relationships (as well as levers such as incentives and penalties in contracts) to take a business on a meaningful emissions reduction journey.

Know how GEP can help your organization in scope 3 emissions reporting.