EPC Procurement & Sourcing Risk: Navigating the Complexities

- Most EPC projects involve sourcing and delivery of large, specialized equipment and materials, stretching the timeline from months to even years

- The significant share of financial risks due to the large capital expenditures and delays or cost overruns significantly impact project profitability

- Collaborating with stakeholders, comprehensive risk mitigation plans, conducting due diligence, and leveraging technology, can help supply chains manage EPC risks

May 22, 2023 | Procurement Strategy 4 minutes read

Engineering, procurement, and construction (EPC) procurement is a critical aspect of large-scale construction projects. From oil refineries and chemical plants to power stations and infrastructure projects, EPC procurement involves the sourcing and management of materials, equipment, and services required for the construction and commissioning of major projects.

EPC procurement is not without its challenges. The complex nature of engineering and construction projects, coupled with the global nature of the supply chain, means that supply chains must navigate a long list of risks to ensure the success of any project.

Let’s explore the key challenges and risks in EPC procurement and the strategies needed to manage them effectively.

Challenges and Risks in EPC Procurement

Managing challenges and risk in EPC procurement is a constant, especially due to long lead times associated with the procurement of major equipment and materials. Most EPC projects involve sourcing and delivery of large, specialized equipment and materials, and the timeline could at times stretch from months to even years from production to delivery. The long lead time usually impacts project schedules and budgets, making it critical for supply chain organizations to work closely with suppliers and ensure timely delivery.

EPC procurement has another significant challenge associated with global supply chains. Risk management is an integral part of EPC projects as they involve sourcing materials and equipment from multiple countries, each with its own unique regulatory, legal, and cultural considerations. Supply chain organizations need to constantly navigate these complexities while ensuring compliance with local laws and regulations.

In addition, EPC procurement has a significant share of financial risks. The projects often involve large capital expenditures, and any delay or cost overrun can have a significant impact on project profitability.

Strategies for Managing EPC Procurement Risks

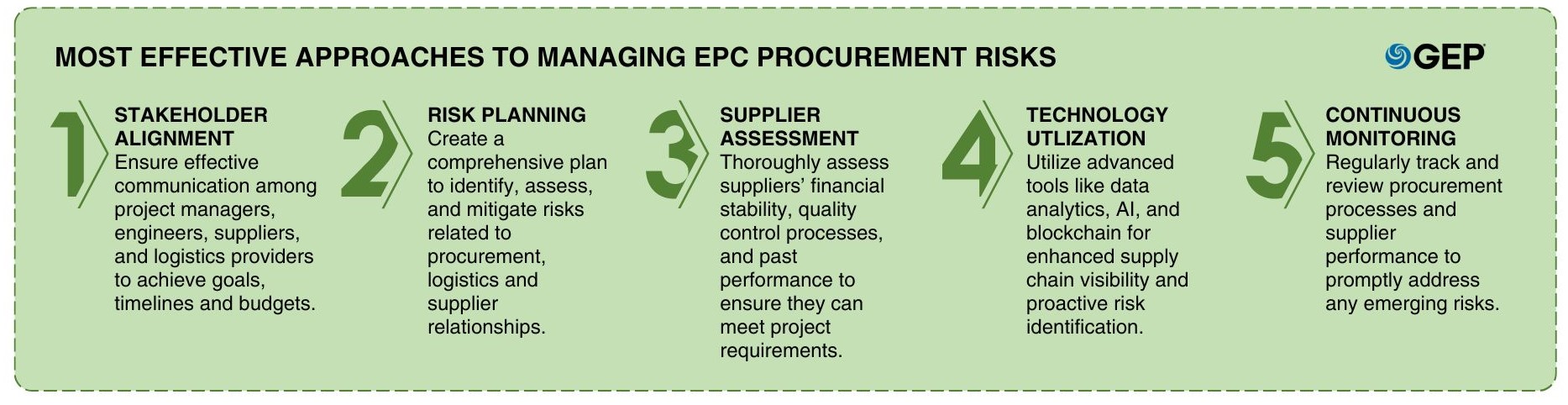

To effectively manage the risks associated with EPC procurement, supply chain professionals must adopt a strategic approach. This includes:

Collaborating with Stakeholders

EPC procurement involves multiple stakeholders, including project managers, engineers, suppliers, and logistics providers. Effective collaboration between these stakeholders is critical to project success. Supply chain professionals must work closely with these stakeholders to ensure that everyone is aligned on project goals, timelines, and budgets.

Developing a Risk Management Plan

Supply chains organizations must always have a ready to deploy comprehensive risk management plan that is in sync with the associated business verticals. Risks are usually associated with procurement, logistics, supplier relationships, and other factors that could impact project success. The risk management plan should be able to identify potential risks and outline strategies and help the enterprise mitigate those risks.

Conducting Comprehensive Due Diligence

Companies must conduct comprehensive due diligence on suppliers and other partners to ensure that they are competent enough to deliver the required products and services — on time and to the required quality standards. Due diligence should typically evaluate a supplier’s financial stability, quality control processes, and past performance.

Leveraging Technology

Technology plays a critical role in EPC procurement risk management. Enterprises can leverage software tools such as data analytics, artificial intelligence, and blockchain to gain comprehensive visibility into the supply chain and identify potential risks beforehand.

Elaborating on Managing Risks

Elaborating on the risk factors in EPC procurement and managing them, minimizing risks is critical. And to minimize risks, companies need to establish clearly defined procurement policies and procedures that fully comply with international regulations and standards.

But first, the procurement process should be transparent, and all related documentation should be kept in order to prove compliance. Enterprises should conduct proper due diligence on potential suppliers, including an end-to-end evaluation of their financial status, quality control processes and experience in delivering similar projects.

Furthermore, a contingency plan should be in place — not as an option but as an essential cog in the process to deal with unexpected events such as supplier bankruptcy or geopolitical crises — to ensure project continuity. Following the aforementioned best practices, companies can mitigate risks and ensure successful EPC procurement.

Conclusion

EPC procurement is a complex and challenging process that requires a strategic approach and careful risk management. Supply chain professionals must navigate long lead times, global supply chain complexities, and significant financial risks to ensure project success. As such, supply chain organizations must carefully manage project budgets and work closely with project managers to ensure that there are no cost overruns and budgets are met. Collaborating with stakeholders, developing a comprehensive risk management plan, conducting thorough due diligence, and leveraging technology, can help supply chain professionals effectively manage the risks and deliver successful EPC projects.