Are you tracking your inventory effectively across warehouses, orders, and transit? Getting this balance right is crucial—too much ties up capital, too little risks stockouts.

GEP's inventory and warehouse management software provides a single, centralized platform to manage both functions seamlessly. By connecting upstream procurement with downstream supply chain systems, you gain real-time visibility to optimize inventory levels, reduce lead times, and lower costs.

What You Get With Inventory and Warehouse Management System

Inventory Management System

Greater Inventory Control

Unlock greater control over inventory with minimal manual intervention for streamlined supply chain operations

Real-Time Inventory Valuation

Get a real-time calculation of inventory valuation by FIFO, LIFO and other methods with seamless data integration with supply chain and finance systems

Enhanced Inventory Tracking & Accuracy

Enhance inventory accuracy and reduce errors through AI-driven systems and next-generation data capabilities

Optimal Inventory Usage

Leverage advanced predictive analytics to optimize inventory usage and availability, and forecast demand accordingly

Warehouse Management System

Real-Time, Anywhere-Anytime Visibility

Track and manage warehouse transactions and tasks on the go with a user-friendly mobile application compatible with handheld devices

Accurate Audits with Cycle Counts

Drive greater speed and accurate inventory audits in warehouses with digital cycle counts during fulfilment or replenishment

Automated Stock Replenishment

Enable highly efficient stock replenishment and receiving with role-based functions and data points capture through OCR capabilities

Streamlined Warehousing Operations

Drive greater automation of key warehouse operations including receiving, issuing, and delivering processes

Next-Generation Warehouse and Inventory Management

With a unified, AI-powered inventory and warehouse management solution, you can centralize inventory management, monitor stock levels, facilitate demand information and generate recommendation-based replenishment orders. What’s more, you also get an advanced view of potential disruptions.

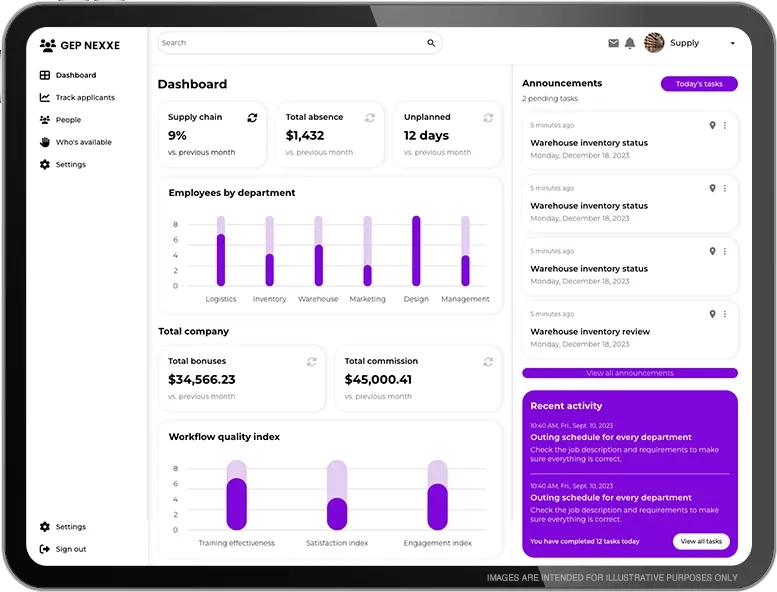

Smart Inventory Management

Manage inventory and warehouse operations on a single software solution with one data model

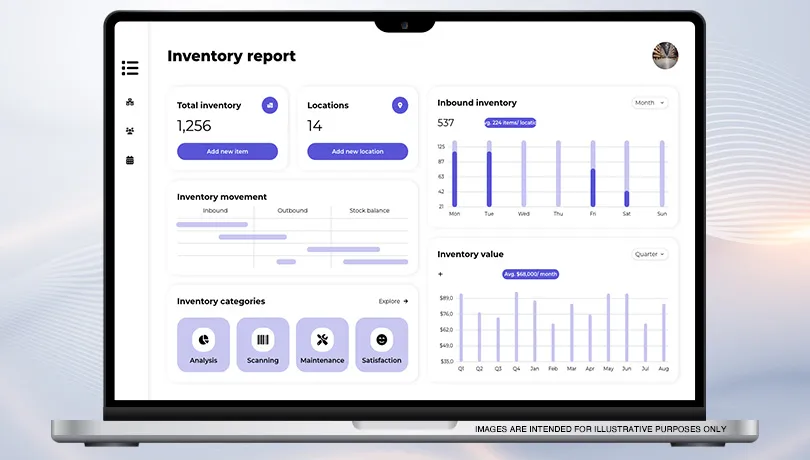

Real-time, Global Inventory Visibility

Get real-time inventory visibility across various locations, including inbound and outbound inventory, all in one dashboard view

Simplified Stock Replenishment

Streamline stock replenishment and receiving with role-based functions. Capture data points through OCR, voice-enabled search and barcode integration

Streamlined Warehousing

Drive greater automation of key warehouse operations including receiving, issuing and delivering processes

Accuracy of Cycle Counts

Digital cycle counts during fulfilment or replenishment enhance speed and accuracy in inventory management

Mobile Application

Track warehouse and inventory operations on the go with a user-friendly mobile application compatible with zebra scanners, barcodes and printers

The Unmatched Value of GEP Inventory and Warehouse Management Software

- Global and granular inventory visibility across locations and modes

- Real-time visibility to tighten up inventory control

- Improved accuracy, reduced errors, consolidated orders, reduced expedited shipping costs

- Reduced inventory carrying and operating costs

Seamless integration with existing ERPs, inventory and supply chain systems and data sources

- Streamlined inventory planning and warehouse operations

- Optimal inventory levels maintained with automated supplier replenishment

Optimal outcomes through collaborative management of inventory with suppliers

Frequently Asked Questions

A warehouse management software automates warehouse operations, helping enterprises gain control and complete visibility over inventory — thereby streamlining supply chain operations across locations. Real-time visibility also means that an enterprise can cut inventory liabilities and tighten inventory control. An automated WMS in place can manage warehouse operations and limit manual interventions during the movement of inventory from the point of origin to delivery.

A modern, cloud-based warehouse management system:

- Enables real-time inventory visibility across all plants/locations/ERP instances, globally

- Carries out all inventory transactions to capture necessary goods movement

- Simplifies warehouse operations via mobile application, bar code scanning, etc. for quick and easy receiving

- Enables material inspection processes, enabling an enterprise to inspect a sample, upload inspection results and take required action in real time

- Integrates with other supply chain tools to drive optimization across end-to-end supply chain

Warehouse management capabilities are now much more than just providing real-time visibility across the supply chain. Data-driven, AI-enabled warehouse management software can now carry out inventory transactions to capture necessary goods movement and can also perform predictive analysis to optimize inventory usage and availability. Warehouse management in future will get further connected with the supply chain, down to the minute details – enabling end-to-end control and paving way for supply chain transformation. It will become a critical part to build an efficient, resilient and sustainable supply chain.

An advanced inventory management software system adds value with its ability to shorten lead times, optimize inventory, prevent stockouts, and reduce storage costs. With AI-enabled systems that come with next-generation capabilities, enterprises can unlock greater control and visibility of inventory across geographies to streamline supply chain operations and drive value across the supply chain.

The best way to keep track of inventory is to move to a cloud-based software platform with integrated warehouse and inventory management software system. Such systems can greatly simplify warehouse operations via mobile application, bar code scanning as well as device compatibility, allowing material handlers to efficiently receive/issue materials on spot from the warehouse.