Why Businesses Need Supplier Performance Management Software

- Without performance management software, businesses experience fragmented processes and low visibility, which can impede growth.

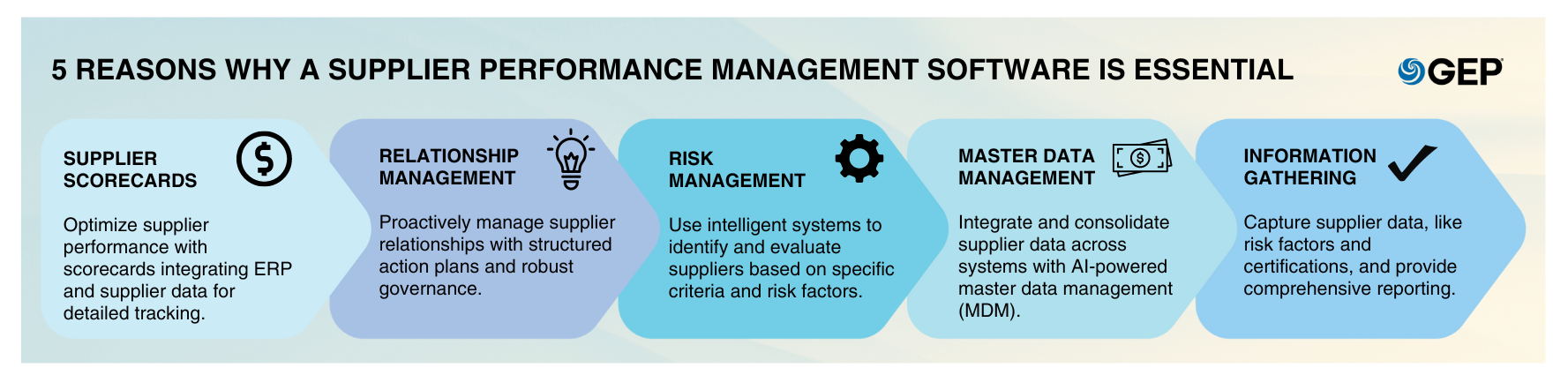

- The software enhances supplier tracking with advanced tools and detailed reporting.

- It supports proactive supplier relationship management and risk assessment.

August 02, 2024 | Supplier Management Technology

Effective supplier performance management is vital for modern procurement, ensuring strong and productive supplier relationships. However, not all businesses able to realize its benefits.

It’s because their legacy systems often fall short in capturing comprehensive supplier data, such as risk factors, social media profiles, corporate responsibilities and certifications.

In the absence of advanced software, organizations face numerous challenges, including incomplete supplier data, inefficient performance tracking and poor supplier relationships.

Without such software, companies struggle with outdated and fragmented records, making it difficult to gather and analyze the full spectrum of supplier information. Manual tracking methods lead to inaccuracies and inconsistencies, hampering the ability to effectively measure and optimize supplier performance. This often results in suboptimal supplier relationships and missed opportunities for improvement.

Benefits of a Supplier Performance Management Software

Enhanced Information Gathering

Accurate and comprehensive supplier information is essential for effective management. While basic details like contact information and financials are readily available, complex data such as risk factors, social media profiles, corporate responsibilities, and regulatory certifications can change over time. Traditional accounts payable and ERP systems often handle only a fraction of this information. As new practices are adopted, the demand for more detailed supplier data increases.

Leading supplier performance management platforms address this need by offering advanced forms and scorecards for unlimited information capture, creating detailed supplier records beyond the constraints of traditional systems.

It also provides full reporting and analysis capabilities, helping to identify suppliers who meet evolving requirements.

Optimizing Supplier Performance with Scorecards

Managing and optimizing supplier performance is critical and challenging. Price alone is insufficient, as substandard services or goods can hinder savings targets. Measuring, evaluating, and tracking supplier performance are essential for realizing projected savings.

The best supplier performance management platform offers comprehensive tools to optimize supplier relationships, tailored to business needs. For instance, supplier scorecards capture both quantitative and qualitative performance data and can be customized by category, country, group, or individual supplier. These scorecards can run automatically, compiling results from ERP systems and supplier information. All performance scores and KPIs are linked to supplier master data within the platform, ensuring detailed performance data is readily accessible for discussions.

Also Read: Actionable Strategies to Tackle Poor Supplier Performance

Proactive Supplier Relationship Management

Having comprehensive supplier information and measuring their performance is essential, but actively managing the relationship is equally important. Knowing that suppliers are underperforming is one thing; helping them improve is another. An effective process for managing this is crucial.

A leading supplier performance management platform offers robust relationship management functionality, providing a structured and transparent way to address poor performance and enhance relations.

Effective supplier relationship management requires active interaction and collaboration, necessitating a strong governance structure, the right engagement model, and focused joint activities. The platform enables the creation of action plans, assignment of stakeholders, and measurement of results for all supplier engagements. Each plan can incorporate multiple actions with different stakeholders, forming a comprehensive strategy for improvement.

With a simple, effective mechanism to manage supplier relationships, you can focus on the next critical task—fostering supplier-driven innovation.

Comprehensive Supplier Intelligence and Risk Management

With vast amounts of supplier information, how do you identify the right suppliers for a new sourcing wave and manage supplier risk proactively? You need a system that evaluates capabilities, credentials, commercials, and experience to ensure the right fit for your business and minimizes global business risk and liability.

An effective supplier performance management system simplifies supplier segmentation and selection. It allows you to assign status flags (preferred, qualified, blacklisted) and meet complex requirements. For example, you can find suppliers who provide specific services in a particular country with strong environmental protection ratings using intelligent search capabilities.

Such a system gives you access to all the information needed to shortlist suppliers based on your unique criteria, making the process quick and easy with just a few clicks or taps.

Supplier Master Data Management

Supplier master data management (MDM) allows procurement organizations to make their supplier master data model more actionable – integrated with the organization’s ERP, accounts payable and other back-office systems to capture all the supplier master data in one place, cleaned and de-duplicated to create the single ‘golden record’ for every supplier, consolidated into the single version of the truth for all supplier records in a central supplier management workspace.

Using AI, supplier MDM tools offer enterprises a quick time-to-value solution. Leveraging cloud, it is capable of integrating all supplier-related records and data from distributed and diverse systems across an enterprise.

It eliminates the time, tedium and guesswork required to manually aggregate supplier records and is a one-system solution for enterprise-wide supplier master data for multiple operations.

To Sum Up

Businesses lacking supplier performance management software face fragmented processes, poor visibility, and inconsistent evaluations, leading to misaligned goals and inefficient progress tracking. A dedicated system enhances information gathering, optimizes performance with scorecards, and supports proactive relationship management.

Learn more about supplier performance management with GEP.