How Predictive Analytics Can Help Build New Supply Chain Capabilities

- Many businesses are increasingly using predictive analytics to build new supply chain capabilities.

- Demand forecasting and risk mitigation are among the many business functions where predictive analytics is making an impact.

- It can also help enhance customer experience by analyzing buying patterns and predicting what customers may buy next.

October 03, 2023 | Supply Chain Software

In recent years, most businesses have seen how unforeseen events and supply chain disruptions can hamper operations and business continuity. Yet many of them do not have the capability to predict such events.

What they do have though is a massive amount of data – structured as well as unstructured – that is generated from different sources in their supply chain.

They must consolidate and make sense of all this data to identify risks and mitigate their impact.

In this endeavor, they can no longer rely on traditional analytical methods that look at historical data and past trends to predict future outcomes. Conventional methods often miss out on key factors that may impact the business in different ways.

So, how can a business make the best use of data and utilize it to its advantage?

The answer is predictive analytics.

What is Predictive Analytics?

Unlike traditional analytical solutions that can work with small datasets and limited variables, predictive analytics can consider several different variables or drivers affecting a business situation.

By making use of statistical tools such as regression analysis, correlation analysis and deep learning, it can establish cause-and-effect relationships between these variables. This helps simulate different business scenarios for planning or predicting the most likely outcomes based on actual conditions.

Simulations form dynamic models by describing the relationship between different components of a system. Running a simulation model estimates the system’s behavior, enabling a business to make accurate predictions.

In simple words, predictive analytics enables a business to anticipate potential challenges before they can occur and impact operations. By anticipating challenges, businesses can act proactively and take preventive steps.

Predictive analytics can also be seen as a logical extension of descriptive and diagnostic analytics, which analyze what happened and why it happened, respectively. It uses the data and insights generated to make predictions about the future.

Nearly 62% of chief procurement officers believe predictive analytics has the capability to disrupt or create competitive advantage for a business with its ability to derive meaningful and actionable insights from data.

There are two significant benefits of leveraging predictive analytics in supply chains.

First, businesses can get better visibility and gain real-time data and insights, which can be used to improve decision-making.

Second, increased visibility can help decision-makers better visualize key KPIs, run if-then analyses and evaluate different scenarios.

Use Cases of Predictive Analytics in Supply Chains

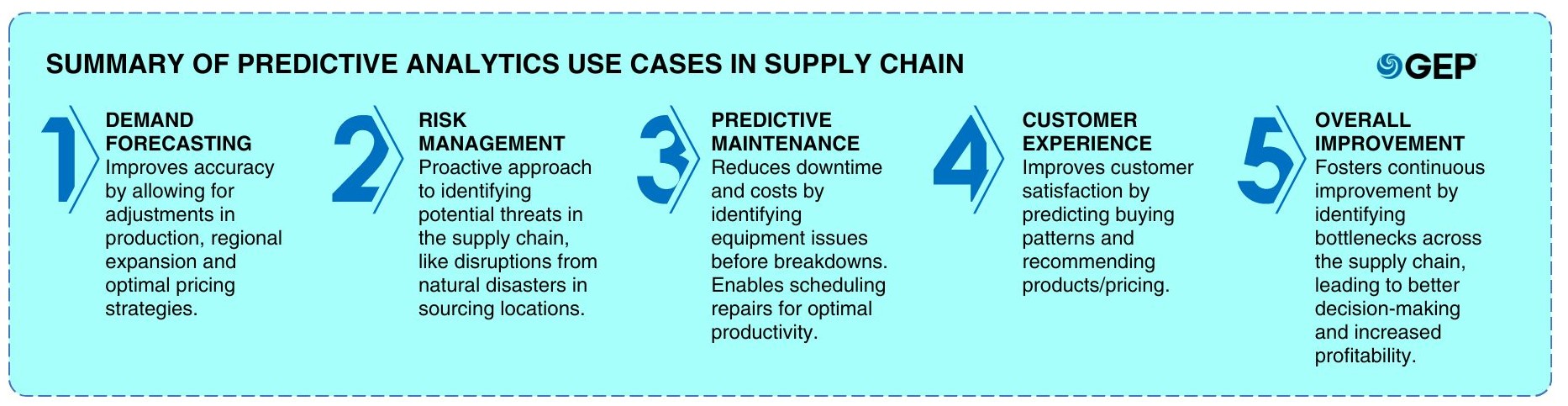

1. Demand forecasting:

Traditional forecasting methods often look at a single variable and provide inaccurate forecasts. Predictive analytics can estimate demand by considering several influencing factors, which enhances accuracy and allows businesses to adjust their supplies accordingly.

It can also estimate demand in a specific region, enabling a business to expand production in that region or look for partners with spare capacities who could provide additional units when sales increase.

It can even determine optimal pricing for a product that is likely to be a hit among customers by analyzing historical sales volumes as well as current market conditions. For example, an analysis of product sales volumes at different price points can help identify the optimum price point.

2. Risk management:

Growing uncertainty in the business environment and prolonged supply chain disruptions have led organizations to adopt a proactive risk management strategy. Predictive analytics helps implement this proactive strategy by auditing each component or process in the supply chain for assessing the potential threat. For example, if a business procures raw materials from an overseas location, predictive risk management would assess all possible sources of disruption including common natural disasters in the region.

3. Predictive Maintenance:

Many businesses now use predictive models in the maintenance process to avoid expensive breakdowns and optimize productivity levels. By identifying potential problems before they occur, predictive analytics solutions help supply chain managers reduce downtime and operational costs. It allows them to schedule repairs ahead of time and maintain high productivity at all times.

4. Customer experience:

In a highly competitive environment, businesses are increasingly using predictive analytics to improve the customer experience. They are exploring ways to understand and predict customer behavior and buying patterns. Predictive analytics can anticipate what customers may buy next and at what price point. By looking at buying data and trends, it can recommend products as well as pricing strategies. It can also classify customers into different segments, letting a business identify which segment is more likely to buy a product.

In addition to the above use cases, predictive analytics can help foster a culture of continuous improvement. It can detect bottlenecks and inefficiencies and identify opportunities for process improvement across different business functions. This enables a business to make smarter decisions, enhance process efficiencies and improve the bottom line.

Also, as predictive analytical solutions need monitoring over time, businesses should monitor their results periodically and fine-tune them to changing conditions to maximize results.