Beyond Spreadsheets: How to Optimize Your Bill of Material Management Process

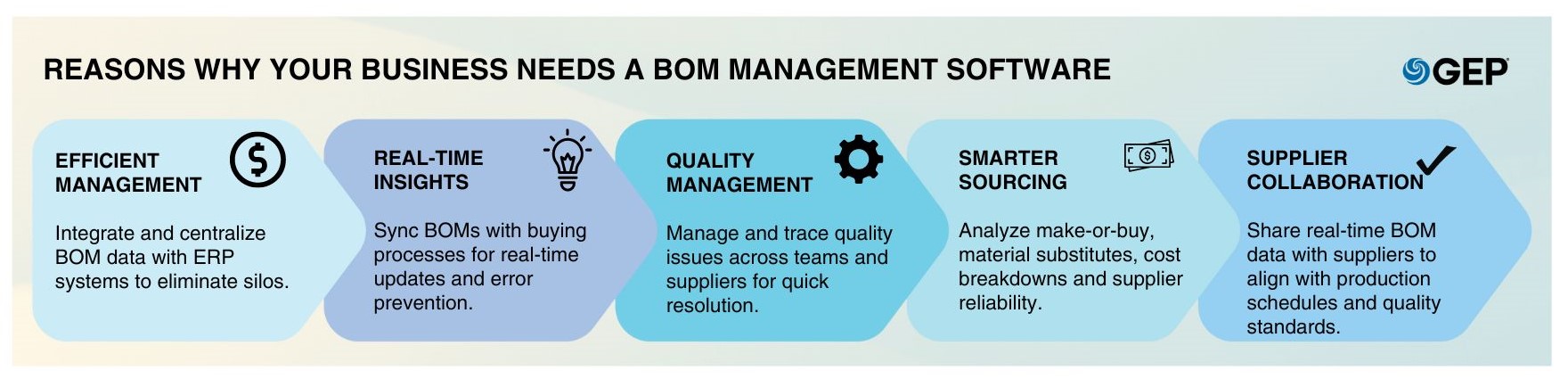

- Integrate multi-level BOMs with ERP systems, eliminate data silos and access centralized BOM data to reduce errors and duplication.

- Synchronize BOMs with buying processes for real-time design changes and better communication between engineering and sourcing.

- Analyze "what-if" scenarios, manage quality issues with traceability features and collaborate with suppliers in real-time.

July 30, 2024 | Procurement Software 3 minutes read

We know that managing bill of materials (BOM) inventory can be a time-consuming and error-prone process – especially for companies with complex products or frequent product revisions.

Many manufacturing enterprises use spreadsheets to manage and maintain BOMs, but this method imposes significant limitations and risks.

Although conventional ERPs and product lifecycle management and manufacturing engineering systems can replace spreadsheets, they often fail to provide reliable, accurate and updated BOM data to sourcing and procurement teams due to a lack of integration.

Common challenges include poor access control, version tracking issues, and duplicate entries, all of which cause delays and increased costs. More importantly, disorganized and incorrect BOMs can result in design and production defects, leading to further cost spikes and production delays.

This is where BOM management software comes into the picture. It can dramatically improve the efficiency of your bill of material management processes to help you meet the necessary increase in demand.

Here are some important ways a BOM inventory management system can benefit your business:

Efficient Management

BOM software lets you integrate multi-level BOMs, connect with your current Enterprise Resource Planning (ERP) systems, and access all BOM data at any time. You can import BOMs from all sources with a single click and gain more control. This eliminates BOM data silos and makes all information available to all relevant stakeholders in one single place, avoiding erroneous or duplicated information.

Better Collaboration and Real-Time Insight

Synchronize BOMs with your buying processes so that you have a real-time view of design changes and component specifications. The real-time ability to communicate between engineering and sourcing processes can prevent production delays, as well as alert sourcing activity. Working across teams and communicating which process owns the information will enable you to share information across departments, eliminating manual process updates that often result in errors.

Also Read: AI In Bill of Materials Software – An Overview

Collaborative Quality Management

Coordinate quality management activities across internal departments and suppliers – from initial sample inspection to managing complaints and audits. Traceability features enable swift identification of quality issues and expedite corrective actions.

Smarter Sourcing Decisions

Utilize the “what-if" functionality to analyze make-versus-buy scenarios or identify viable material substitutes. Maintain a library of component options and analyze cost breakdowns of different BOM versions to make informed sourcing decisions. The software also evaluates lead times and supplier reliability to ensure the timely availability of the right materials.

Supplier Collaboration

Foster a collaborative approach that accelerates product innovation throughout the lifecycle. Ensure line-item visibility and access to vendor-approved part numbers. Communicate design specifications with suppliers. By giving suppliers real-time BOM data visibility, you ensure they align with production schedules and quality requirements.

To Sum Up

BOM management software empowers companies to achieve efficiency gains, better products, lower costs and a competitive edge. It acts as the central nervous system of your manufacturing operations, ensuring everything runs smoothly and efficiently, leading to a more robust and innovative ecosystem.