How Additive Manufacturing Revolutionizes the Procurement Process

- Additive manufacturing accelerates lead times by eliminating tooling and molds, allowing on-demand production.

- It enhances customization and flexibility by enabling bespoke parts creation without expensive retooling.

- This technology fosters localized supply chains, reducing reliance on complex international systems.

July 02, 2024 | Procurement Strategy

Every manufacturer strives to be efficient in procurement and shorten production cycle times. That is why we are seeing many manufacturing leaders explore the potential of additive manufacturing.

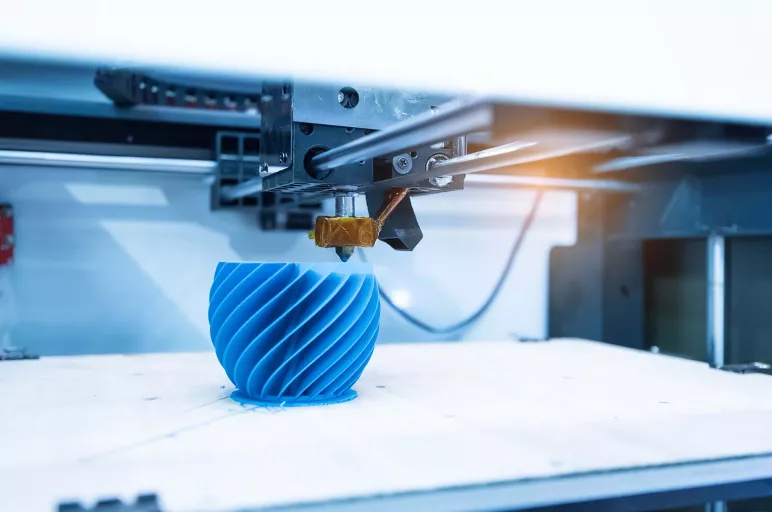

Additive manufacturing is a group of technologies that create three-dimensional (3D) objects – building up one layer at a time. Objects can either be made of plastic, metal or other materials.

Imagine you manufacture shoes. Additive manufacturing has the potential to revolutionize your business. It allows you to streamline production processes by 3D printing key components on an industrial scale, such as mid-soles and outer soles. This innovation paves the way for the possibility of additively bonding the soles to the shoe uppers, enhancing speed, efficiency and production flexibility.

1. Accelerated Lead Times

Traditional manufacturing requires extensive lead times as the process requires tooling and molds and needs supply chains of their own. Additive manufacturing avoids all these steps, enabling simple digital models to manufacture parts. This means that parts can be sourced and arrive quicker than ever before, reducing downtime and optimizing time-to-market on new production lines. For instance, in sectors such as aerospace and healthcare, where speed is essential, this ability is transformative.

2. Inventory Reduction and On-Demand Production

Inventory levels represent one of the major procurement challenges, where minimizing cost must be balanced by maintaining sufficient levels of availability. Having excess inventory on hand ties up capital and drives storage costs, while stockouts can halt production lines. Additive manufacturing allows companies to produce parts in quantities based on demand, rather than purchasing and storing them in warehouses. This minimizes inventory costs while removing the risks of overstocking and stock-outs. Companies can operate with optimal inventories and fulfill customer needs considerably faster with additive manufacturing.

3. Enhanced Customization and Flexibility

Bespoke differentiation is the basis of many markets. Yet traditionally, making custom parts has been a slow and expensive process. Additive manufacturing easily prints tailored items, with no need for expensive retooling. An organization’s procurement department can easily access bespoke parts as needed, whether that is a one-off or small batch. This flexibility means that organizations can more easily cater to niche customer requirements and react rapidly to changing demands.

4. Supply Chain Localization

Volatility – whether it’s caused by geopolitical events, natural disasters, or logistical breakdowns – can negatively impact global supply chains. Additive manufacturing can help by enabling parts to be produced locally. When parts are produced locally, it reduces reliance on complex international supply chains. Seamless logistics is a natural consequence of localized production. This translates to lower transportation costs and a more reliable supply chain. Procurement teams can mitigate a range of risks in their supply chains and ensure that crucial components won’t be stuck at a distant seaport when needed by localizing supply chains.

Also Read: Procurement Success Toolkit - Fresh Procurement Strategies

5. Cost-Effective Low-Volume Production

Large production runs are often infeasible with traditional manufacturing because of the high setup cost the process demands. By comparison, additive manufacturing incurs barely any setup costs – making bespoke one-offs much cheaper. This allows for low-volume parts to be produced economically as a prototype, a custom job, or a limited-edition item. Companies can thus source components without radical adjustments to production costs, enabling greater innovation and experimentation.

Conclusion

Additive manufacturing allows for faster lead times, lower inventory costs, greater customization, simpler supply chains, and making low-volume production more cost-effective. As this technology becomes more pervasive and integrated, procurement professionals will be able to create ever-resilient manufacturing supply chains.