Achieving Next-Gen Resilience Through Supply Chain Management Software Modules

- Implementing integrated supply chain management modules in high-impact areas leads to improved visibility, intelligence and collaboration.

- The critical modules include demand forecasting, should-cost modeling, PO collaboration, logistics visibility and warehouse and inventory management.

- By methodically digitizing operations through purposeful module adoption, supply chains can achieve next-generation resilience and agility.

December 29, 2023 | Supply Chain Software

Implementing new technology ranks among the most pivotal initiatives supply chain leaders can undertake to improve operations.

In recent Economist Insight research commissioned by GEP, 63% of procurement and supply chain leaders surveyed indicated that adopting technology to increase supply chain visibility is a top priority.

At the same time, many leaders still delay upgrades in order to preserve status quo systems.

Yet, savvy leaders know that prioritizing purposeful digital integration projects focusing on high-impact areas can unlock tangible benefits through supply chain software modules.

Resistance often roots in anticipated disruption, the broad scope of transformation projects, and the perceived difficulty quantifying ROI.

But the cost of inaction grows by the day. Siloed processes, reactionary fire drills in response to disruptions, and limited visibility exact a heavy toll in the form of margin leakage, excess inventory and supply volatility.

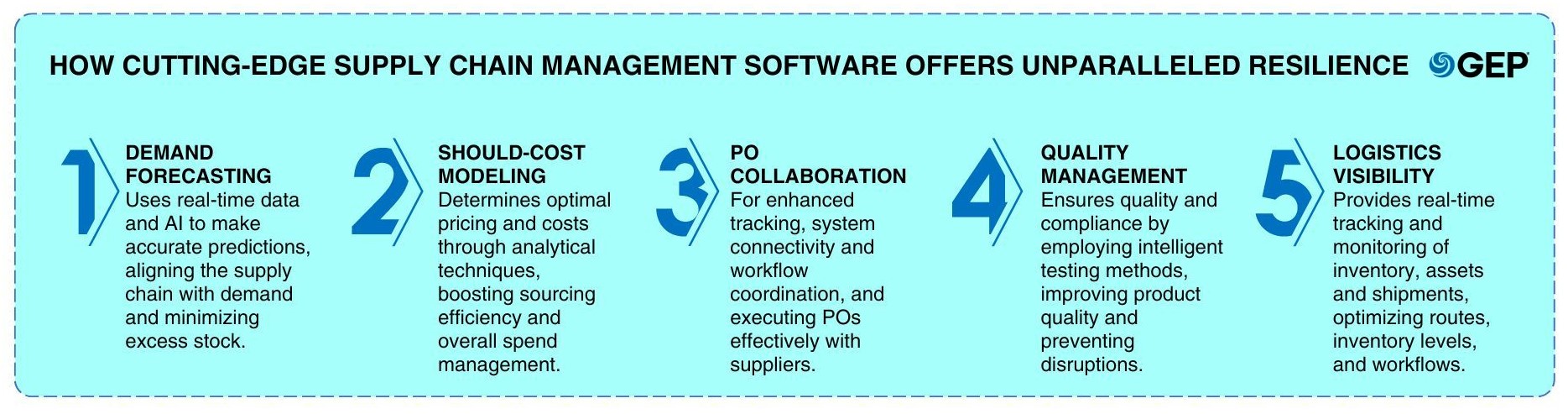

What are the key modules to look for when deploying a new supply chain management software platform? The foremost modules delivering proven returns across supply chain operations include:

Demand Forecasting & Planning

Demand forecasting and planning leverages real-time data and advanced AI to sense and predict future customer demand across multiple time horizons. By analyzing historical data, trends, and signals from across the supply chain, it enables accurate demand predictions that feed into production planning, inventory optimization and sales and operations planning.

As the foundation for aligning supply with demand, reducing excess stock, and improving customer service levels, demand forecasting and planning is an essential supply chain process for maximizing revenue and profitability while minimizing waste. Implementing demand forecasting and planning solutions is key for supply chain leaders looking to improve their organization's overall planning capabilities and operational resilience.

Should-Cost Modeling

Should-cost modeling is a strategic approach used to determine optimal pricing and costs for purchased goods, materials, and services. By using analytical techniques like market analysis, value engineering, and data modeling, should-cost modeling establishes competitive benchmark pricing and targets for supplier negotiation. This method drives efficiency in sourcing decisions and spend management, crucial to maximizing value and reducing waste in the supply chain.

Should-cost modeling delivers the critical data needed to make informed strategic decisions, making it essential for supply chain leaders aiming to optimize their organization's overall supply chain performance.

Purchase Order Collaboration

Leveraging centralized platforms, purchase order collaboration enables enterprises to track transactions, connect systems and coordinate workflows across the entire PO lifecycle. By providing inventory visibility, intelligent order orchestration, and shipment consolidation, order management maximizes efficiency.

Having resilient and adaptive order collaboration capabilities is crucial for supply chains to efficiently create, approve, execute and receive purchase orders and invoices in collaboration with suppliers.

Quality Management

Quality management encompasses the strategic practices of ensuring quality and compliance across global procurement, manufacturing, and logistics operations.

By establishing intelligent quality testing, standardization, inspection procedures and corrective action loops, supply chain leaders can improve product quality while preventing disruptions.

Implementing technology solutions to gain end-to-end visibility further enables predictive quality management via data analysis.

Digitally managing quality processes will allow organizations to reduce operational and compliance costs while exceeding customer expectations – key pillars of resilient, sustainable supply chains .

Logistics Visibility

Logistics visibility provides real-time tracking and monitoring of inventory, assets, and shipments across the end-to-end supply chain.

By connecting systems and data feeds across transport, warehouses, yards, and other logistics nodes, companies can gain integrated visibility via advanced analytics and control towers.

Logistics visibility enables optimization of routes, inventory buffers and workflows for greater efficiency. Supply chain leaders can leverage predictive visibility and event management to significantly reduce logistics costs, improve on-time, in-full delivery, ensure compliance and drive sustainable growth. With multidimensional logistics visibility, organizations can rapidly adapt to volatile market conditions.

Inventory & Warehouse Management

Warehouse and inventory management are essential to enabling efficient, resilient and optimized supply chain operations.

By tightly coordinating people, processes and technologies across warehouse activities, organizations gain the accuracy and speed to optimize inventory costs, monitor stock levels and generate recommendation-based replenishment orders.

Leveraging automation, analytics, and visibility tools allows for precise inventory tracking and optimization across networks, keeping availability high while reducing waste.

As key drivers of supply chain agility and efficiency, advanced warehouse and inventory management capabilities empower supply chains to meet demand profitably amidst constant change. With end-to-end optimization, leaders can fulfill orders seamlessly.

Progressing to Next-Generation Supply Chains

While individual capabilities drive value, integrating modules creates force multiplier effects since data synchronizes automatically. This interoperability saves effort otherwise required in moving data manually across disjointed systems. Leaders gain holistic operational intelligence to guide decisions through sophisticated analytics.

But technology alone cannot transform supply chains. Realizing benefits requires focus on change management, user adoption and governance to instill solutions as a way of working.

By methodically digitizing operations through purposeful module adoption, supply chains progress maturity to new heights. Leaders should prioritize accordingly to deliver next-generation supply chain resilience and agility.