Procurement in Manufacturing: Challenges & Best Practices

- A timely supply of materials at a competitive cost translates to better customer satisfaction and a competitive advantage.

- Utilize machine learning for demand forecasting and build strong, collaborative relationships with reliable suppliers prioritizing quality.

- Automate tasks like purchase orders and leverage data analytics for informed decisions on inventory management.

June 18, 2024 | Procurement Strategy

Procurement is an essential part of a manufacturing company’s operations, enabling it to conduct a timely and efficient supply of materials, components or services.

With manufacturing becoming extremely competitive, improving procurement practices is vital to sustaining the business and maximizing cost efficiency, and product and service quality.

Here's how subpar procurement can cripple your operations:

Production Bottlenecks:

A single part delayed by a supplier can cost you a long downtime. It can also lead to a shutdown of the entire assembly line.

Excess Inventory:

Outdated or unusable items in warehouses tie up working capital. It can also create storage challenges and even safety problems. This capital could be reallocated to invest in innovation or production expansion.

Damaged Reputation:

If the raw materials used are of low quality, the finished products will suffer as well. In the worst-case scenario, unsafe products could become subject to a widespread recall.

Procurement Best Practices for Manufacturers

Demand Forecasting:

Forecasting is important, but the digital age has seen old-school methods become outdated. Embrace cutting-edge tools like machine learning (ML) to crawl through historical sales data, production schedules, and even social media to make accurate demand predictions.

Beyond Price:

When evaluating and choosing your strategic sourcing partner, do not limit focus on cost. Identifying a manufacturing partner who will be reliable in delivering your products, understanding the complexity of each product run and the specifications and tolerances are equally important.

Other factors to consider are suppliers with robust quality management systems and certificates and those who align with your ESG goals.

Supplier Relationship Management:

Invest in building long-term, collaborative relationships with your key suppliers. This involves communicating openly and sharing information on both sides, solving problems together, and working jointly to anticipate and manage issues such as disruptions in the supply chain. Consider programs for supplier development to help your partners improve their capabilities and align with your changing needs.

Rigorous Quality Assurance:

Collaborate with suppliers to establish and maintain strict quality standards specific to your needs. This might involve conducting supplier audits, implementing quality control checks at multiple stages, and utilizing statistical process control (SPC) to monitor and improve quality across all stages of the supply chain.

Streamlined Purchasing & Order Management with Automation:

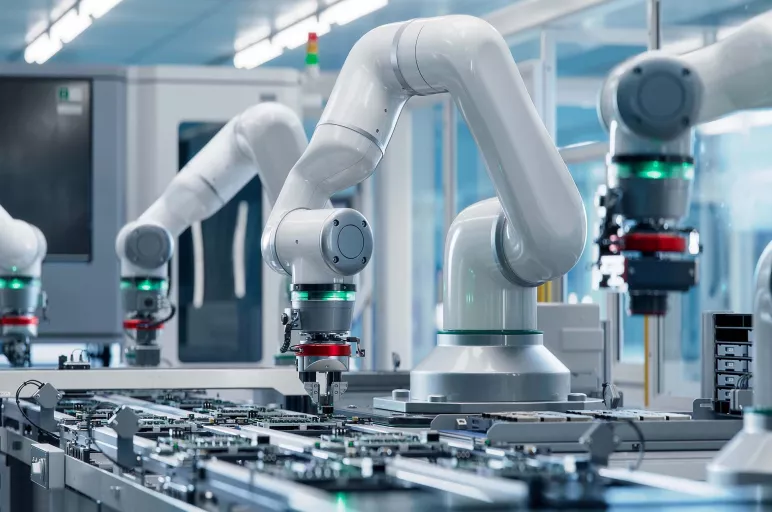

Tasks like purchase order generation, invoicing processing and correspondence with suppliers have a large manual component that can be automated with technology. Moreover, real-time data analytics offer valuable visibility that offer data-driven decisions on order and stock management.

Also Read: Assessing the Benefits and Risks of Contract Manufacturing

Challenges and Solutions for Manufacturers in a Volatile Market

Challenge 1: Fluctuating Price

Solution:

Reduce risk by diversifying suppliers and using hedging contracts to lock in raw material prices in volatile markets.

Challenge 2: Supply Chain Disruptions

Solution:

Keep some buffer stock of critical materials and have alternative sourcing options available. Develop contingency plans to take into consideration the possibility of a natural disaster, political crisis or even a global pandemic.

Challenge 3: Data Fatigue

Solution:

Invest in procurement software that can mine big data from all sources – internal production data, supplier performance data, market trends, public procurement opportunities and so on.

To Sum Up

Effective procurement in manufacturing is essential as it means a timely supply of materials at the best price – resulting in more customer satisfaction. Effective procurement encompasses demand forecasting to working with chosen suppliers and performing quality controls. Technologies like machine learning can power demand forecasting and automation tools can help with streamlined purchasing to optimize procurement.