4 Steps Supply Chain Leaders Can Take Now Toward Net-Zero Goals

- Many organizations have goals to achieve net-zero emissions, but action is lacking

- To eliminate Scope 3 emissions, firms need to collaborate with partners across their value chains

- With new tools available to aid in data collection and reporting, the best time to start working toward net-zero is now

May 13, 2022 | Supply Chain Strategy

The concept of net zero emissions is fairly new yet simple – it means lowering new emissions to the atmosphere in an attempt to limit the global temperature rise. Companies can do this by either reducing emissions from their activities and from their supply chains, or offsetting emissions through natural carbon sinks.

According to a recent report from Energy and Climate Intelligence Unit, 21% of the world’s 2,000 largest public companies, representing $14 trillion in sales, have committed to achieving net zero emissions.

However, as the number of companies that commit to net zero targets and report on emissions and climate risks continues to climb (and as the requirements for reporting on climate risks increase), there is often a gap between commitments and actual reductions.

Emissions from supply chain can make up a high percentage of total emissions for most organizations. So, the question for many supply chain leaders is: how do they start closing that gap?

There are several steps that companies can take to make real progress on the road to net zero:

1. Map your supply chain

Reporting requirements are likely to expand in the future, so companies should start today to map their supply chains, baseline their Scope 3 emissions and understand their exposure to climate-related risks.

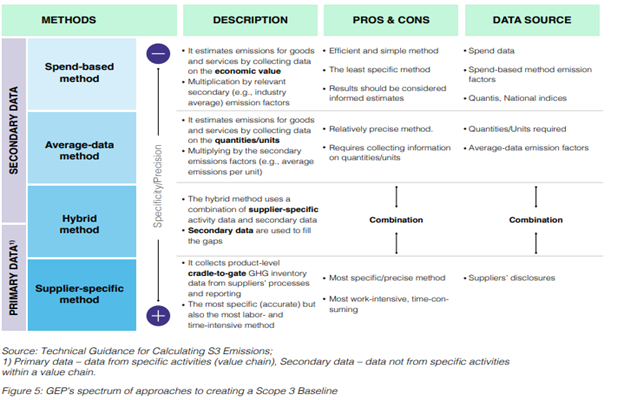

There are a number of approaches to determining baseline emissions (as shown in the table below). So, choose the method that makes the most sense for your enterprise:

2. Identify strategic suppliers

It’s extremely difficult to try to implement a sustainability target across an entire global supply chain all at once. It’s far simpler to start by identifying the strategic suppliers your enterprise partners with and leverage them to bend the curve on Scope 3 emissions. Determining which suppliers have the maturity and scale to already be addressing their emissions can make a huge difference.

3. Build collaboration with suppliers and business partners

Reducing Scope 3 emissions depends greatly on collaboration with suppliers and trading partners. It requires trust in the data that is often self-reported by suppliers and a willingness to collect and share that data. Supply chain collaboration platforms assist companies to close the gaps that exist between them and their supply chain partners, making it easier to capture and analyze the right data.

4. Align KPIs to a sustainability mindset

Different elements of an enterprise’s supply chain track success using different metrics, which can obscure the total cost involved in each stage of the supply chain. Price doesn’t equal cost – for example a procurement organization that focuses solely on the lowest-cost suppliers may not be looking at the bigger picture in terms of sustainability.

Embedding sustainability metrics or scorecards in procurement and supply chain platforms can help companies move toward decisions that reduce both costs and emissions — without forcing them to rework their business process.

Also Read: New SEC Proposal on Climate-Related Disclosures: Key Challenges and Opportunities for Enterprises

Start now to get ahead of the curve on meeting sustainability targets

Making supply chains more sustainable by pursuing net-zero targets isn’t just good for the environment, it can also be good for a company’s bottom line.

Achieving greater efficiencies saves money and the environment, and in an uncertain economic climate that’s increasingly impacted by climate risks and disruptions, it can be a key factor in building resilience as well as a component of competitive advantage and brand image.

In the long run, it doesn’t just make sense for the planet for firms to earnestly pursue net-zero targets, it makes sense for shareholders as well. And with the tools available now to help enterprises do that more effectively than ever, it doesn’t make sense to wait any longer.

To learn more about how to get your enterprise on track to meet ESG commitments, and examples of firms that are already on the path, download our white paper, “How to Achieve True Net-Zero Emissions: An Action Plan for Supply Chain Leaders”.