Optimizing Mechanical Equipment Sourcing and Supply Chain: Strategies for Success

- Optimizing the mechanical equipment sourcing and supply chain helps enterprises reduce lead times, improve product quality, and substantially reduce costs

- Advanced analytics can help enterprises identify supply chain risks and opportunities and enable them to make informed decisions

- Strong supplier relationships can enable enterprises to build a reliable and resilient supply chain that can withstand unexpected disruptions and challenges

May 25, 2023 | Sourcing Strategy

Mechanical equipment sourcing and mechanical equipment supply chain management are critical components of industrial operations. Navigating the sourcing and supply chain aspects of mechanical equipment requires a deep understanding of the industry and the industry-specific strategic approach to procurement. A wide range of products — including pumps, motors, compressors, and generators, used in various industries such as manufacturing, construction, and energy — classify as mechanical equipment.

This blog explores the key factors that procurement and supply chain functions need to consider so that the mechanical equipment sourcing and supply chain management processes can be streamlined.

Role of Technology in Mechanical Equipment Sourcing

Technology has revolutionized the process of mechanical equipment sourcing and supply chain management — making it easier and more efficient than before. With increasing numbers of e-commerce and digital platforms, supply chain organizations can now get quick and easy access to a global network of suppliers and vendors. This means that the best products can be sourced at the best prices, thereby streamlining the procurement process exponentially. The advanced analytics driven by AI and ML can also help identify supply chain risks and opportunities — allowing enterprises to make informed decisions.

That said, technology comes with its own set of challenges. Increasing digitalization also increases an enterprise’s vulnerability to cyber threats and data breaches. To counter that, organizations need to stay on their toes at all times to protect their sensitive information. The cybersecurity protocol needless to say has to be robust, and this requires regular training for employees and an enterprise-wide proactive approach to risk management to close any loophole in the system.

Strategic Sourcing in Mechanical Equipment Procurement

Strategic sourcing is a critical aspect of mechanical equipment procurement. And taking the strategic approach to sourcing enables procurement and supply chain functions within an enterprise to identify cost savings opportunities, negotiate better deals with suppliers, and ensure quality and reliability of products. Strategic sourcing also involves identifying potential risks and developing the required contingency plans.

Supplier relationship management is an important aspect in strategic sourcing. Developing and maintaining close relationships with suppliers help enterprises in multiple ways — such as improved communication, timely delivery of products, and collaboration on product development and innovation over the long term.

Standardization is another critical aspect in strategic sourcing of mechanical equipment. It not only streamlines the procurement process, but also enables enterprises to improve quality control and reduce costs. It also enables easy comparison of products from different manufacturers, enabling procurement and supply chain functions to make informed decisions.

Fostering strong relationships with suppliers and open lines of communication can also enable enterprises to build a reliable and resilient supply chain that can withstand unexpected disruptions and challenges.

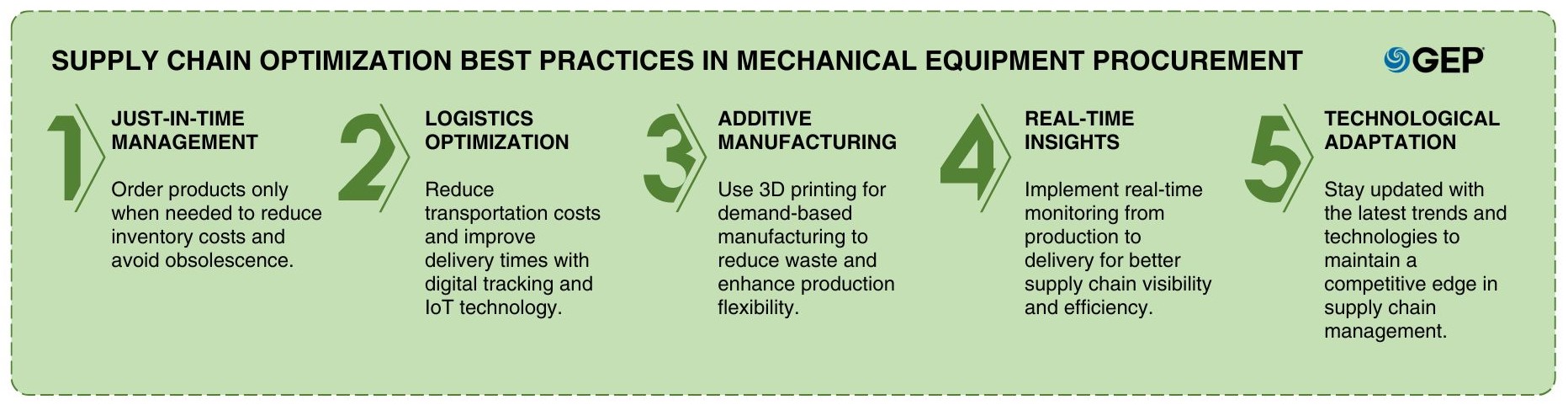

Supply Chain Optimization in Mechanical Equipment Procurement

Optimizing the supply chain helps enterprises reduce lead times, improve product quality, and substantially reduce costs. But this requires a comprehensive understanding of the supply chain, including the many components and processes involved in sourcing and delivering mechanical equipment products.

Just-in-Time (JIT) Inventory Management

JIT inventory management involves ordering products only when they are needed, resulting in reduced inventory carrying costs and freed-up capital for important investments. JIT inventory management also addresses the risk of product obsolescence, ensuring products are delivered only when they are needed.

Logistics Optimization

Optimizing logistics substantially reduces transportation costs and improves delivery times. It also ensures that products are delivered in the specified condition. Logistics optimization with digital tracking and IoT technology ensures that enterprises can now get real-time insights — from the production floor to the transportation carrier to the customer’s receiving dock.

Additive Manufacturing

Additive manufacturing, also known as 3D printing, could enable supply chains to cater to demand-based manufacturing of parts. This would not only reduce the burden on supply chains, but also create a sustainable value chain for long-term benefits. The technology ensures waste reduction, faster production times and greater design flexibility. But what this essentially implies is that supply chain professionals now need to keep up with the latest trends and technologies.

Conclusion

Managing mechanical equipment sourcing and supply chain is complex. Enterprises need to deploy processes that require a strategic approach, the latest technology, and optimization strategies for an efficient supply chain. By leveraging the aforementioned strategies — including developing strong relationships with stakeholders and suppliers and by keeping up with the latest industry trends — supply chain organizations can help improve product quality, reduce costs, and ensure the reliability of their mechanical equipment products.