Is Automation the New Normal for Industries?

July 23, 2020 | Inventory Management

COVID-19 created economic turmoil as industries, factories, businesses of all sizes came to a halt. Many industries and businesses reported losses due to supply chain disruption, lack of demand and extreme pressure on operational costs. Conversely, businesses dealing with essential items such as pharmaceuticals, PPE and personal care were under pressure as demand for these products soared overnight.

This global crisis has persuaded companies to innovate to mitigate supply-demand risks. Companies and businesses that were not that aggressive in adopting automation have started to leverage technology to help them cut costs during the pandemic and are trying to refurbish their operations.

Automation for Sanitization and Social Distancing

With increasing cases of COVID-19, the demand for sanitizing products has soared tremendously. UVD Robots, a Danish manufacturer of UV light disinfection robots, have shipped many of their machines to different hospitals across regions such as China and Europe. Further adoption of this technology can be expected in schools and offices even post-COVID.

With social distancing prevailing even after the ease in lockdown restrictions, automation is expected to be at the forefront to maintain distance and minimize contact between guests and staff. Many restaurants have started to adopt robots for cleaning to avoid contact with humans. Many hotel chains have already started implementing mobile applications and digital keys for a seamless check-in and check-out. Hilton’s Digital Key is one of many examples of guests using their smartphones as a room key.

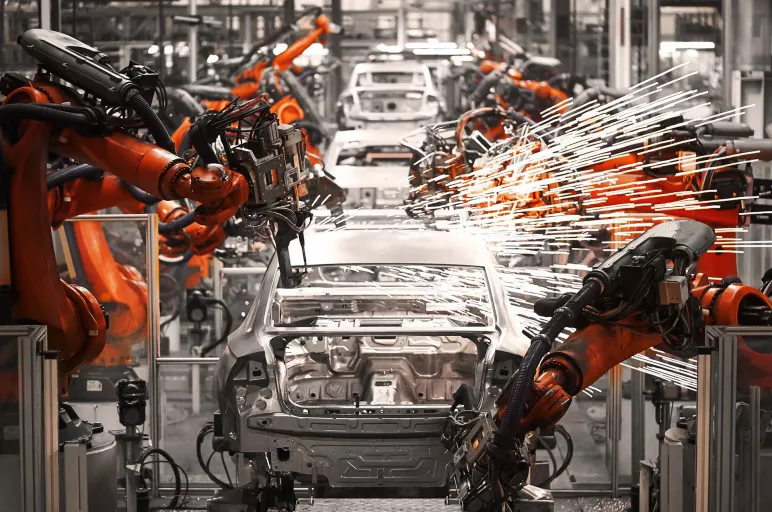

Automation in the Manufacturing Industry

The rise of robots in the automobile manufacturing sector was inevitable. However, the use of programmable industrial robots to make the production process simpler has been highlighted during the pandemic. As manufacturers try to observe social distancing on the production floor, there has been a rise in the use of automation or robots. These can help manufacturers not only have an uninterrupted production but also enable safer and more efficient production.

Automation to Reduce Inefficiencies in Health Care

The daily surge in COVID-19 cases has showcased the inefficiencies in health care systems worldwide. One example where automation can be used to make health care more efficient is updating patient records. As the number of patients continue to rise, a shortage of available nurses poses a problem for the healthcare sector. Furthermore, nurses are required to spend more than 7 hours a week on paperwork, which increased during the pandemic. Many hospitals are adopting automation to ensure nurses are free to take care of patients instead of updating records.

Conclusion

Studies have found that companies who opted for automation technologies earlier are observing an increase of more than 6% in revenue, offering them an advantage over their peers. COVID-19 has forced industries to operate with reduced human interaction in order to control the spread of the disease. The adoption of automation is expected to increase productivity, reduce manual dependency, and augment and create new jobs. Companies worldwide are reconsidering their supply chain models to prevent any further mishaps in the future. The adoption of automation is likely to provide these industries and companies with the sustainability, efficiency, and reliability needed during uncertain times.

References

- https://www.industryweek.com/technology-and-iiot/article/21129334/what-will-manufacturings-new-normal-be-after-covid19

- https://www.bbc.com/news/technology-52340651

- https://www.forbes.com/sites/shahinfarshchi/2020/04/10/expect-more-jobs-and-more-automation-in-the-post-covid-19-economy/#3baddb829b40

- https://www.business-standard.com/article/economic-revival/service-robots-may-increase-efficiency-of-covid-19-impacted-hotels-report-120060800984_1.html

- https://www.roboticstomorrow.com/article/2020/04/covid-19-impact-on-food-automation-and-robotics-market/15179