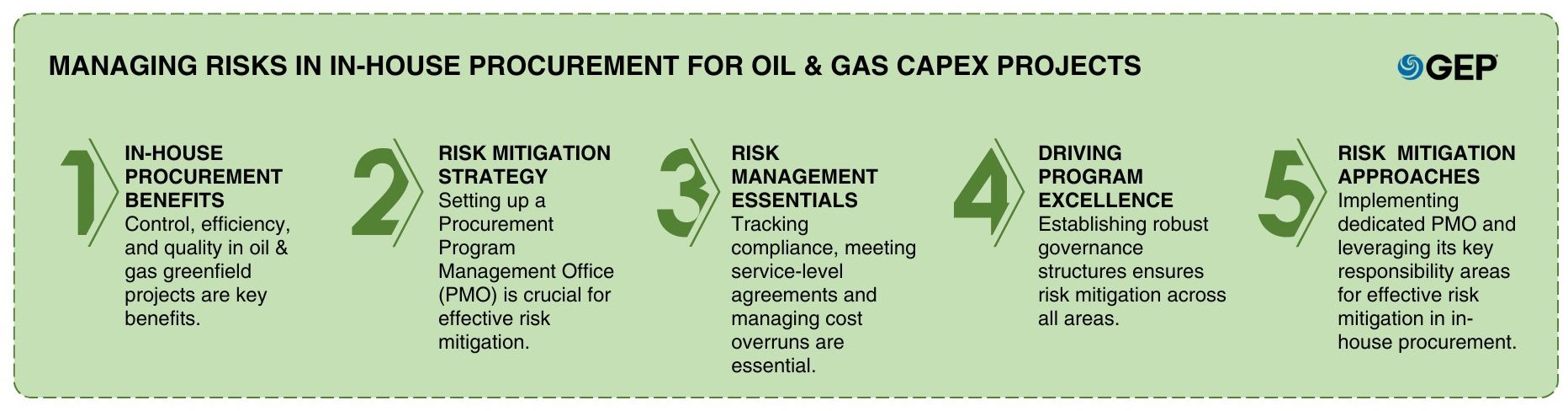

Managing Risks in In-House Procurement for Oil & Gas Capex Projects

- In-house procurement offers control, efficiency and quality in oil & gas greenfield projects.

- Setting up a procurement program management office (PMO) is key to effective risk mitigation.

- The PMO could focus on performance measurement, documentation control, and cost overrun management and optimizing procurement processes.

May 29, 2023 | Procurement Strategy

When it comes to procurement in the oil and gas industry, there are two main approaches: in-house procurement and the engineering, procurement, and construction (EPC) option.

In the in-house model, the organization handles the whole procurement process internally, from sourcing to managing contracts.

On the other hand, the EPC model involves hiring an external contractor to handle the procurement process. The in-house alternative is gaining traction.

In this blog post, we explore risk mitigation in in-house procurement for greenfield capital projects in the oil and gas industry.

Determining Risks in In-House Procurement

While in-house procurement has its benefits, it doesn’t come without potential risks. These risks include schedule delays, cost overruns, quality issues, liability concerns and project management issues. However, by putting in place effective risk mitigation strategies, enterprises can minimize these risks and maximize the benefits of in-house procurement. Let's explore some of these strategies.

Setting up a Procurement Program Management Office

One way to mitigate risks in in-house procurement is by setting up a dedicated procurement program management office (PMO). This office acts as the central hub, providing oversight and ensuring proper governance, reporting, and performance management. It plays a key role in coordinating various aspects of procurement. For instance, a global energy company can establish a PMO to manage the procurement process for its new refinery project. The PMO tracks compliance, ensures that service-level agreements are met, and offers expert guidance to the internal procurement team, minimizing the risk of project delays and cost overruns.

Key Responsibility Areas for Risk Mitigation

Within the PMO, specific key responsibility areas contribute to effective risk mitigation. These include tracking compliance and status, meeting service-level agreements, leading strategic initiatives, coordinating with suppliers, managing orders and deliveries, controlling documentation, and managing cost overruns. For example, a natural gas producer can form a PMO responsible for overseeing the procurement of drilling equipment. The PMO monitors supplier coordination, shipment tracking, order delivery, and quality testing, reducing the risk of delays and ensuring timely project completion.

Driving Program Excellence

By implementing a robust governance, reporting, and performance management structure through the PMO, companies can effectively manage operational delivery, stakeholder relationships and risk. This approach ensures that risk mitigation measures are put in place across all areas, driving program excellence and reducing the likelihood of complications. For instance, a renewable energy company can establish a PMO to manage the procurement of solar panels for its large-scale projects. The PMO could focus on performance measurement, documentation control, and cost overrun management, optimizing procurement processes and minimizing risks.

Minimizing risks in oil and gas procurement calls for a proactive approach. By establishing a dedicated procurement program management office and leveraging its key responsibility areas, organizations can effectively mitigate risks in in-house procurement.

To know more about in-house procurement, download our white paper Capex in Oil & Gas: Why In-house Procurement Is Better Than EPC Model