Struggling to Monitor Scope 3 Emissions? Here’s a Framework to Get Started

- Businesses must take immediate steps to monitor their scope 3 emissions.

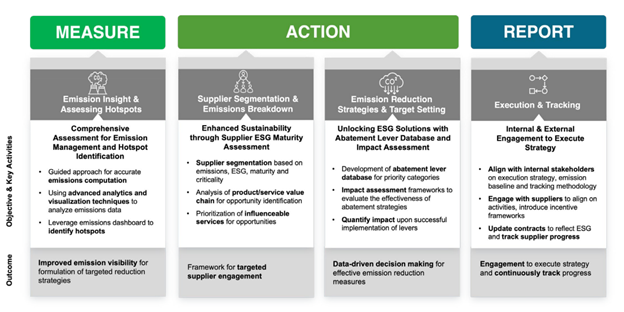

- They can leverage a measure-action-report framework to effectively manage these emissions as well as to track progress over a period.

- This framework places procurement at the forefront of emission reduction strategy and implementation efforts.

August 20, 2024 | Sustainability

Many businesses even today are focusing merely on containing their direct — scope 1 and scope 2 — emissions. They are not paying heed to scope 3 emissions, which originate in their supply chains and account for more than 70-80% of their total emissions.

Where’s the Disconnect?

A recent study by North Carolina State University in collaboration with GEP highlights that only a quarter of enterprises are focusing on reducing their scope 3 emissions.

The remaining enterprises tend to overlook their suppliers, partners and the broader supply chain ecosystem. Or they do not have adequate, high-quality data from suppliers and other third parties.

Even if they have some data, they do not have skilled resources who can interpret this data. Lack of standardization makes the task of measuring and monitoring emissions even more challenging.

Many companies find it challenging to meaningfully engage with hundreds of partners in their upstream and downstream operations.

However, despite all these challenges, it is vital for enterprises to firstly measure these emissions and secondly to think of ways to minimize them.

Regulatory bodies in different regions are becoming increasingly stringent on these emissions.

So, how can enterprises act quickly and find ways to manage these emissions?

Let’s find out.

To Manage Emissions, Measure, Action and Report

To simplify the process, companies must break up their emissions management program across 3 fundamental buckets of measure, action and report.

The objective here is to integrate current internal data systems, external supplier footprint and business operational model. Such integration helps frame a strategic plan to undertake sustainability transformation without hurting operations.

The measure-action-report methodology allows companies to create customized abatement levers for different spending categories. It also facilitates the initiation of supplier collaboration, selection or substitution.

Source: www.gep.com

Measure:

In this phase, companies do comprehensive assessment for emission management and hotspot identification. They use advanced analytics and visualization techniques to analyze emissions data. They can also leverage advanced tools such as emissions dashboards to improve visibility, identify hotspots and formulate targeted strategies.

Action:

Companies now segment their suppliers based on their emissions data, ESG maturity and criticality. This segmentation helps to prepare a framework for targeted supplier engagement. They can also analyze their product or service value chain to identify potential opportunities.

Next, companies prepare emission reduction strategies, set targets and develop abatement lever database for priority categories. They also engage in impact assessment to evaluate the effectiveness of abatement strategies. The objective here is to make data-driven decisions by quantifying the impact of implementing levers.

Report:

This phase involves strategy execution by engaging with internal and external stakeholders. Internal stakeholders need to align on execution strategy, emission baseline and tracking methodology. Likewise, businesses should engage with their suppliers to align on various activities. They should educate them about any incentive frameworks. They should also update supplier contracts to reflect ESG performance and track their progress over a period.

Implementing an Action Plan

When companies have an action plan, they know their targets, timelines and overall priorities. They can also monitor progress through key performance indicators and service level agreements.

The action plan broadly includes:

1. Supplier segmentation:

Segment the supplier base to build a framework based on emissions, ESG maturity and criticality.

2. Supplier engagement:

Identify key suppliers to focus on. Define priorities based on targets and criticalities.

3. Incentive and innovation pipeline:

Introduce an incentive framework to run a prioritized engagement plan. Update supplier contracts and restructure SRM programs by incorporating ESG metrics.

4. Implementation and governance:

Use project management and reporting tools to ensure successful implementation.

A Lot Depends on Procurement

The role of procurement is key to implementing a sustainability strategy and working with a measure-action-report framework.

With the help of this framework, procurement can not only meet compliance requirements but also drive innovation. This capability can provide the much-needed edge in a highly competitive business environment.

Still wondering how to leverage the measure-action-report framework in your organization? Read the new white paper to learn 10 steps associated with the framework.